Dress Tech Pack - Complete Manufacturing Guide with Examples

A dress tech pack is a 6–12 page technical document that specifies how a factory should construct your dress — including flat sketches with closure and seam details, bust-waist-hip measurements with grading rules, a bill of materials separating shell fabric from lining, construction methods for hems and darts, and zipper or button specifications. Because dresses must conform to the body's curves, they require more precise measurements than most garments, and incomplete dress tech packs are the most common cause of fit-related sample rejections.

This guide breaks down the five essential components of a factory-ready dress tech pack, common mistakes to avoid, and how to generate one in minutes. New to tech packs? Start with our complete guide to fashion tech packs.

Table of Contents

- What is a Dress Tech Pack?

- Key Components of a Dress Tech Pack

- 1. The Flat Sketch: Closures & Seams

- 2. Measurements: The Holy Trinity (Bust-Waist-Hip)

- 3. Bill of Materials (BOM): Shell vs. Lining

- 4. Construction: Hems & Darts

- 5. Grading for Dresses

- Common Dress Tech Pack Mistakes

- Create Your Dress Tech Pack in Minutes

- Frequently Asked Questions

What is a Dress Tech Pack?

A Dress Tech Pack (or Specification Sheet) is the instruction manual for your garment. Because dresses vary so wildly in style—from knits to wovens, minis to maxis—the tech pack serves to standardize the production method.

It answers the invisible questions:

- Entrance: How does the customer get into it? (Zipper? Buttons? Stretch?)

- Structure: Is it lined? Does it have interfacing in the collar?

- Fit: What is the ratio between the waist and the hips?

Without these answers, a factory will make the easiest version of your design, which is rarely the high-quality version you envisioned.

Key Components of a Dress Tech Pack

Using Adstronaut AI, you can organize the complexity of dress manufacturing into a structured 12-tab workflow. Here is how to use it for dresses.

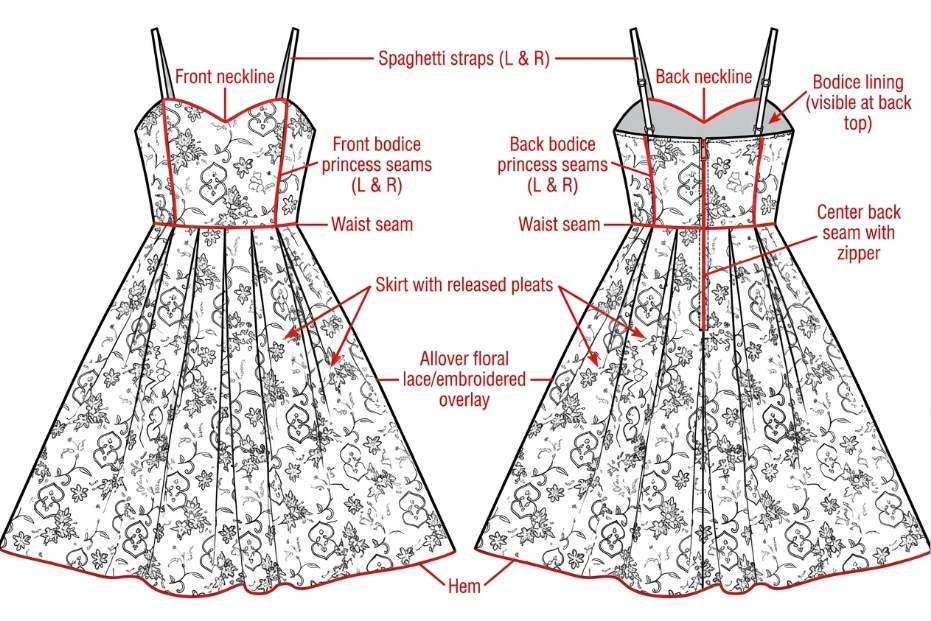

1. The Flat Sketch: Closures & Seams

The sketch is the map. For dresses, the most important details often live on the Back View or the Side View.

Critical Details to Sketch:

- Zipper Placement: Is it a Center Back (CB) zipper or a Side Seam zipper?

- Darts: Where are the bust darts or waist darts located to create shape?

- Seam Lines: Is there a waist seam, or is it a princess seam running down the body?

Adstronaut AI Feature: When you upload your dress reference photo, our AI generates a clean vector-style sketch. This is crucial for annotating the Closure Method. You can use the Garment Callouts tab to point to the back of the dress and label: "Invisible Zipper, starts 2cm below neckline, ends at hip."

Technical flat sketch of a midi slip dress showing front and back views on blueprint grid.

Technical flat sketch of a midi slip dress showing front and back views on blueprint grid.

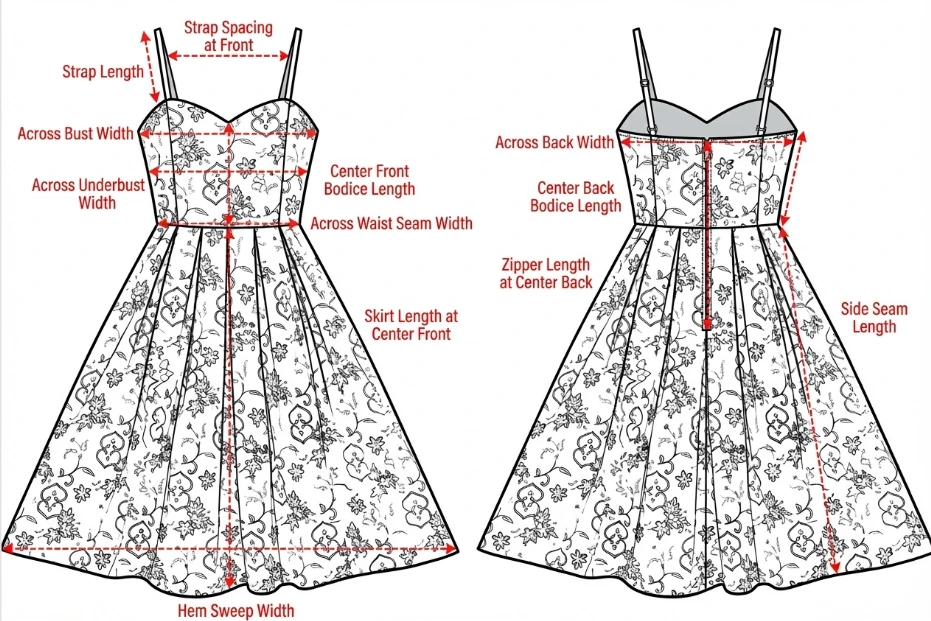

2. Measurements: The Holy Trinity (Bust-Waist-Hip)

In menswear or casual wear, you can get away with loose measurements. In dresses, the relationship between the Bust, Waist, and Hip is everything.

The "Point of Measure" (POM) Guide:

- Bust: Measured 1" below the armhole.

- Waist: Measured at the narrowest point (or a specific distance from the shoulder).

- Hip: Measured at the widest point (usually 7-9" below the waist).

- Sweep: The width of the bottom hem (critical for walking room).

Adstronaut AI Feature: Use the Sample Measurements tab to draw these lines precisely. You can drag a line across the waist of the sketch and define exactly where that measurement should be taken (e.g., "14 inches from HPS"). This prevents the factory from guessing where the "waist" sits.

Sample Measurements tab showing measurement lines at Bust, Waist, and Hip.

Sample Measurements tab showing measurement lines at Bust, Waist, and Hip.

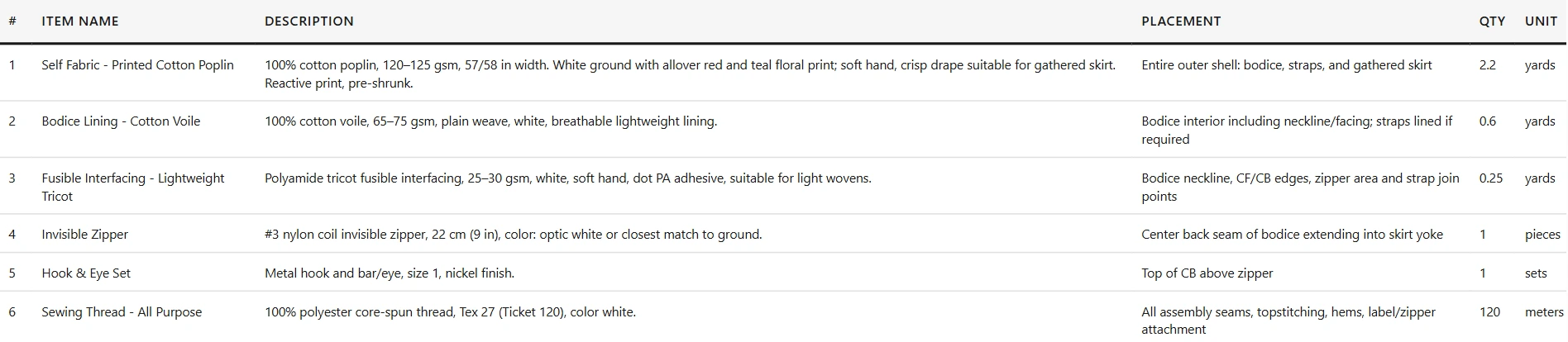

3. Bill of Materials (BOM): Shell vs. Lining

Most high-quality dresses are not just one layer of fabric. They consist of a Shell (the outside fabric) and a Lining (the inside fabric).

Why Separation Matters: The shell might be an expensive Silk Georgette ($20/yard), while the lining is a cheap Polyester or Rayon ($3/yard). If you don't list them separately in the BOM, the factory might try to fuse them or use the wrong material for the lining.

Adstronaut AI Feature: The BOM tab allows you to create distinct rows for "Shell Fabric" and "Lining Fabric." It also lets you specify "Fusible Interfacing"—the stiff material hidden inside collars and cuffs to make them stand up.

BOM showing Shell Fabric, Lining, Invisible Zipper, and Fusible Interfacing.

BOM showing Shell Fabric, Lining, Invisible Zipper, and Fusible Interfacing.

4. Construction: Hems & Darts

How the dress is finished defines its price point.

- Hems: A "Baby Hem" is used for light fabrics like chiffon. A "Blind Hem" is used for formal trousers and skirts so no stitching shows. A standard "Turnback Hem" is used for cotton day dresses.

- Darts: Darts are folds sewn into the fabric to provide shape. Your tech pack must specify the length of the dart apex.

Adstronaut AI Feature: Use the Construction Guide tab. You can input instructions like: "All internal seams to be French Seamed" (a high-end finish that hides raw edges) or "Baby hem on bottom sweep."

Macro shot showing invisible zipper installation perfectly matching fabric color (DTM).

Macro shot showing invisible zipper installation perfectly matching fabric color (DTM).

5. Grading for Dresses

Grading a dress is complicated because you aren't just making it bigger; you are keeping the proportions. If you make the waist 2 inches wider, do you also make the bust 2 inches wider? Not necessarily.

Adstronaut AI Feature: The Size Table automates this logic. You can set different grading rules for different areas.

- Grade Rule: Bust +1" per size.

- Grade Rule: Length +0.5" per size (tall girls wear larger sizes, but not always proportionally taller).

Common Dress Tech Pack Mistakes

- Forgetting the Opening: You design a beautiful fitted dress but forget to put a zipper in the tech pack. The factory makes it, and the model can't get it over her head.

- Lining Hanging Out: If you don't specify that the lining length should be 1 inch shorter than the shell, the lining will peek out the bottom of the dress.

- Wrong Zipper Type: Specifying a standard coil zipper instead of an "Invisible Zipper" will ruin the clean lines of a formal dress.

Create Your Dress Tech Pack in Minutes

Dresses require precision. Don't risk your production budget on a sketch and a prayer.

Adstronaut AI provides the professional structure needed to define your layers, closures, and fit points clearly.

- Upload your dress photo.

- Define your shell and lining in the BOM.

- Annotate the zipper placement and hem finish.

- Export a factory-ready PDF.

Turn your sketch into a perfect sample, the first time. Learn the full process in our how to create a tech pack guide, or see more tech pack examples across 10 garment categories.

Generate your Dress Tech Pack for free!

Frequently Asked Questions

What does DTM mean in a tech pack?

DTM stands for "Dyed to Match." You use this for buttons, zippers, and thread. It tells the factory that the zipper shouldn't be a standard color, but must be dyed to match the exact shade of the dress fabric.

Do I need a tech pack for a simple slip dress?

Yes. Even a slip dress requires precise measurements for the strap length, the bias cut of the fabric (which affects drape), and the finishing of the neckline. Simple garments often require more precision because flaws are easier to see.

What is the difference between a measurement spec and a grade rule?

The Measurement Spec is the actual number (e.g., Waist = 28"). The Grade Rule is the formula for how that number changes between sizes (e.g., +/- 1" per size).

How many measurement points does a dress tech pack need?

A standard dress tech pack requires 12–18 points of measure (POMs), including bust, waist, hip, shoulder width, across front, across back, armhole depth, sleeve length (if applicable), neck drop, center front length, center back length, hem sweep, and slit length. Fitted dresses and those with princess seams may require additional POMs for dart placement and seam positioning.

What information does a factory need about a dress lining?

Your tech pack must specify the lining fabric type (typically polyester, rayon, or cupro), weight (usually 60–80 GSM for lightweight linings), color (DTM or contrast), attachment method (sewn in, tacked at seams, or free-floating), and length relative to the shell (typically 1 inch shorter than the outer hem to prevent peeking). Failing to specify lining details is one of the top 3 dress tech pack errors.

Should I include a garment wash instruction in the dress tech pack?

Yes. Include the intended care label instructions (hand wash, machine wash, dry clean only) and specify any garment wash treatments (enzyme wash, silicone softener) that affect the finished look and hand feel. Factories use this information to select compatible thread, trims, and construction methods that will survive the specified care process.

Sources and further reading:

- ASTM D5585 — Standard Table of Body Measurements for Adult Female Misses Figure Type (measurement standards for women's dress grading)

- Maker's Row — Guide to Working with Clothing Manufacturers (tech pack best practices for factory communication)

- Adstronaut AI — The Complete Guide to Fashion Tech Packs (comprehensive tech pack overview)