Tech Pack Examples - 10 Real Factory-Grade Tech Packs Analyzed

One of the biggest hurdles for emerging fashion brands isn't designing the clothes—it's formatting the documentation. You might have a vision, but if you send a factory a sketch without a standardized system for measurements, materials, and callouts, you will get a sample that looks nothing like your idea.

Designers often ask: "What does a finished tech pack actually look like for my specific category?"

A hoodie requires different technical data than a bikini. A blazer needs structural details that a t-shirt doesn't. However, all professional tech packs share a universal "Factory-Grade" structure.

In this article, we break down 10 distinct garment types. For each, we analyze the specific challenges of that category and show how Adstronaut AI's 12-step tech pack structure ensures you cover every critical detail manufacturing partners require. For a deeper understanding of tech pack fundamentals, start with our complete guide to fashion tech packs.

Table of Contents

- The Universal 12-Tab Structure

- 1. The T-Shirt: Mastering the Basics

- 2. The Hoodie: Managing Hardware & Layers

- 3. Denim Jeans: Construction & Wash

- 4. Activewear Leggings: Stretch & Seams

- 5. The Summer Dress: Silhouette & Lining

- 6. The Tailored Blazer: Internal Structure

- 7. Streetwear Cargo Pants: Utility Details

- 8. Knitwear Cardigans: Yarn & Gauge

- 9. Swimwear: Precision & Elasticity

- 10. Bags & Accessories: Reinforcement

- Automate Your Tech Pack Structure

The Universal 12-Tab Structure

Before diving into specific garments, it is vital to understand the framework. A messy Excel sheet won't cut it. Adstronaut AI automatically generates a comprehensive 12-tab project file for every garment you upload, ensuring no section is missed.

Adstronaut AI organizes every tech pack into 12 essential tabs automatically.

Adstronaut AI organizes every tech pack into 12 essential tabs automatically.

Factories expect these core sections:

- Product Info: Season, Style #, Description.

- Measurements & Sketches: Interactive sketches with precise Points of Measure (POM).

- Size Table: Automated grading rules (S, M, L, XL).

- BOM (Bill of Materials): Every fabric, button, and thread.

- Construction Guide: Sewing instructions and finishings.

Let's see how this structure applies to real-world examples.

1. The T-Shirt: Mastering the Basics

The t-shirt is the foundational garment of the fashion industry. While it seems simple, the difference between a luxury tee and a cheap giveaway is entirely in the Grading (sizing) and Material specs.

The Challenge: Getting the neck drop and sleeve length consistent across sizes.

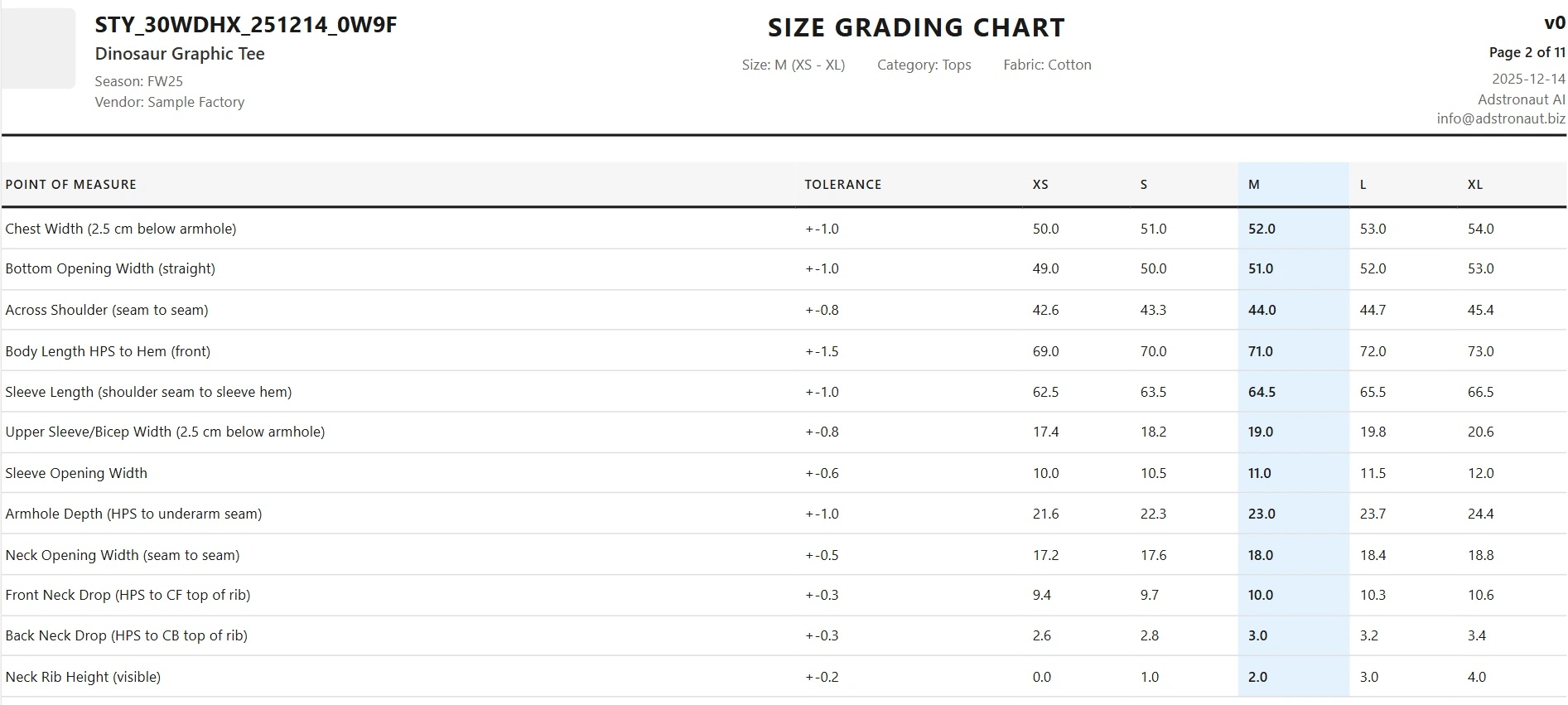

The Tech Pack Solution: For a T-shirt, the Size Table tab is your most critical section. Adstronaut AI generates the base measurements from your image. You then use the table to define the "Grade Rule"—for example, instructing the factory that the chest width increases by 2 inches for every size jump.

For a complete deep-dive into t-shirt specifications, see our dedicated T-shirt tech pack guide.

The Size Table tab showing graded measurements across all sizes.

The Size Table tab showing graded measurements across all sizes.

2. The Hoodie: Managing Hardware & Layers

Hoodies are "high-liability" garments because they involve mixed materials (fleece body vs. ribbing) and hardware (eyelets, drawstrings).

The Challenge: Ensuring the factory doesn't forget the eyelets or use the wrong color drawstring.

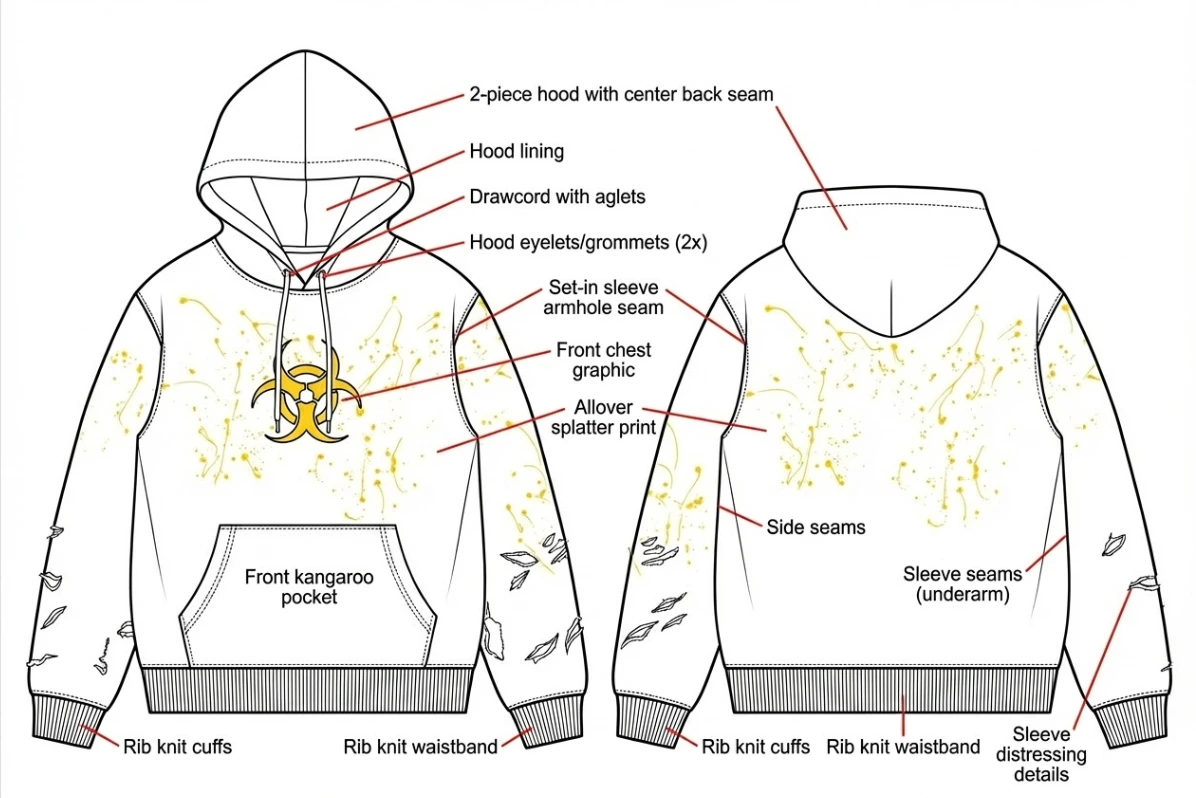

The Tech Pack Solution: This is where the BOM (Bill of Materials) tab shines. The AI detects visible components from your photo. The tech pack provides a structured table where you list the main fleece, the ribbing for the cuffs, the metal eyelets, and the drawstring tip type. The Garment Callouts tab allows you to point exactly where these items go on the sketch.

For detailed hoodie specifications including oversized fits, check our hoodie tech pack guide.

Garment Callouts tab showing numbered labels pointing to hood, pocket, and cuffs.

Garment Callouts tab showing numbered labels pointing to hood, pocket, and cuffs.

3. Denim Jeans: Construction & Wash

Denim is less about the pattern and more about the assembly and finish. It is a heavy-duty construction process.

The Challenge: Communicating topstitching placement and rivet locations.

The Tech Pack Solution: Jeans rely heavily on the Detailed Drawings and Construction Guide tabs. A factory needs to know exactly where to place bar tacks (reinforcement stitches) on pockets. The Adstronaut structure includes zoomed-in views, allowing you to highlight rivet placement on the coin pocket and specify the topstitch color (usually contrasting gold or orange).

Close-up showing rivet placement and topstitching specifications.

Close-up showing rivet placement and topstitching specifications.

4. Activewear Leggings: Stretch & Seams

In activewear, the sewing method is just as important as the fabric. Using the wrong stitch results in seams that burst during a workout.

The Challenge: Specifying specialized stitching for 4-way stretch fabrics.

The Tech Pack Solution: The Construction Guide tab is essential here. While a standard tech pack might just say "sew side seam," an activewear pack must specify "Flatlock Stitching" (ISO 607) to prevent chafing. The Adstronaut AI layout provides a dedicated text area for these sewing instructions, ensuring the factory uses the correct machinery.

5. The Summer Dress: Silhouette & Lining

Dresses often have complex inner constructions that aren't visible from the outside, such as linings or facings.

The Challenge: Ensuring the lining doesn't hang lower than the main fabric.

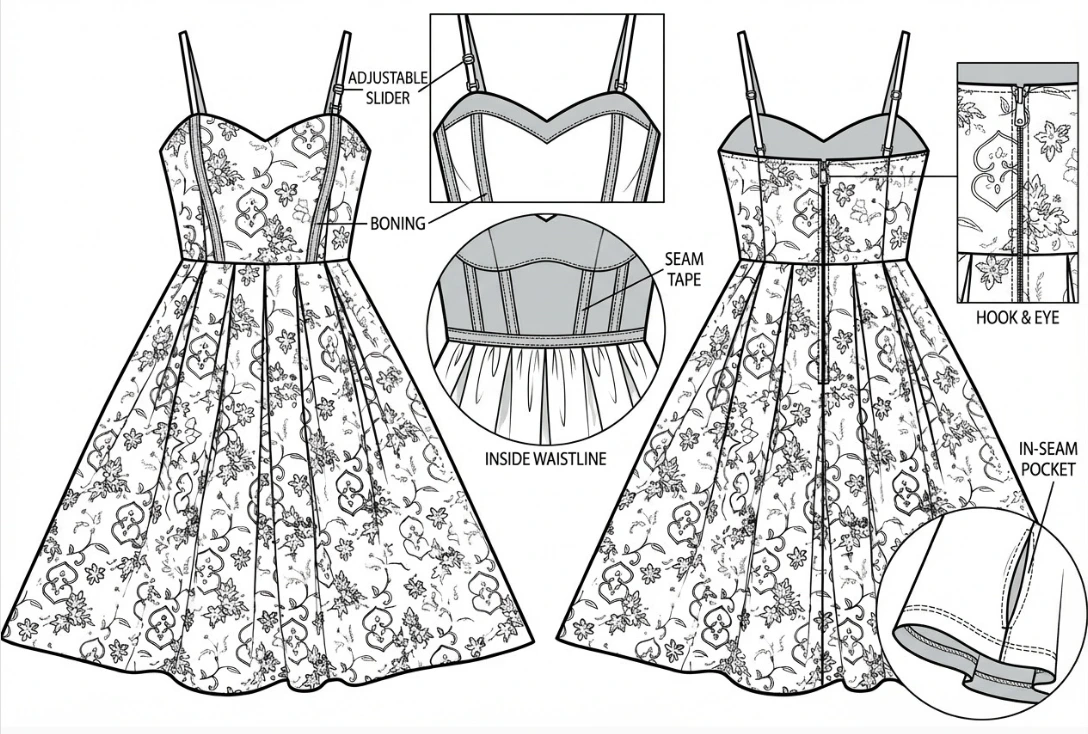

The Tech Pack Solution: The Detailed Drawings tab allows you to separate the "Shell" (outer layer) from the "Lining" (inner layer). You can use the AI-generated flat sketch to annotate hem heights, ensuring the lining is cut shorter than the self-fabric. This prevents the dreaded "exposed lining" mistake in production.

For zipper placement, dart positioning, and more, see our comprehensive dress tech pack guide.

Detailed Drawings tab showing zoomed-in hem and neckline construction.

Detailed Drawings tab showing zoomed-in hem and neckline construction.

6. The Tailored Blazer: Internal Structure

Tailoring is about what you can't see: shoulder pads, interfacing, and button stays.

The Challenge: Listing all the invisible ingredients that give the jacket its shape.

The Tech Pack Solution: The BOM tab for a blazer is extensive. Adstronaut AI's structure allows you to add rows for non-visual items. You use this section to list "Fusible Interfacing" (the glue-like fabric that stiffens collars) and "Shoulder Pads." Without these line items in your BOM, the factory will produce a floppy, unstructured shirt instead of a jacket.

7. Streetwear Cargo Pants: Utility Details

Streetwear is defined by complexity: bellows pockets, zippers, velcro, and straps.

The Challenge: Communicating the functionality of 3D pockets on a 2D piece of paper.

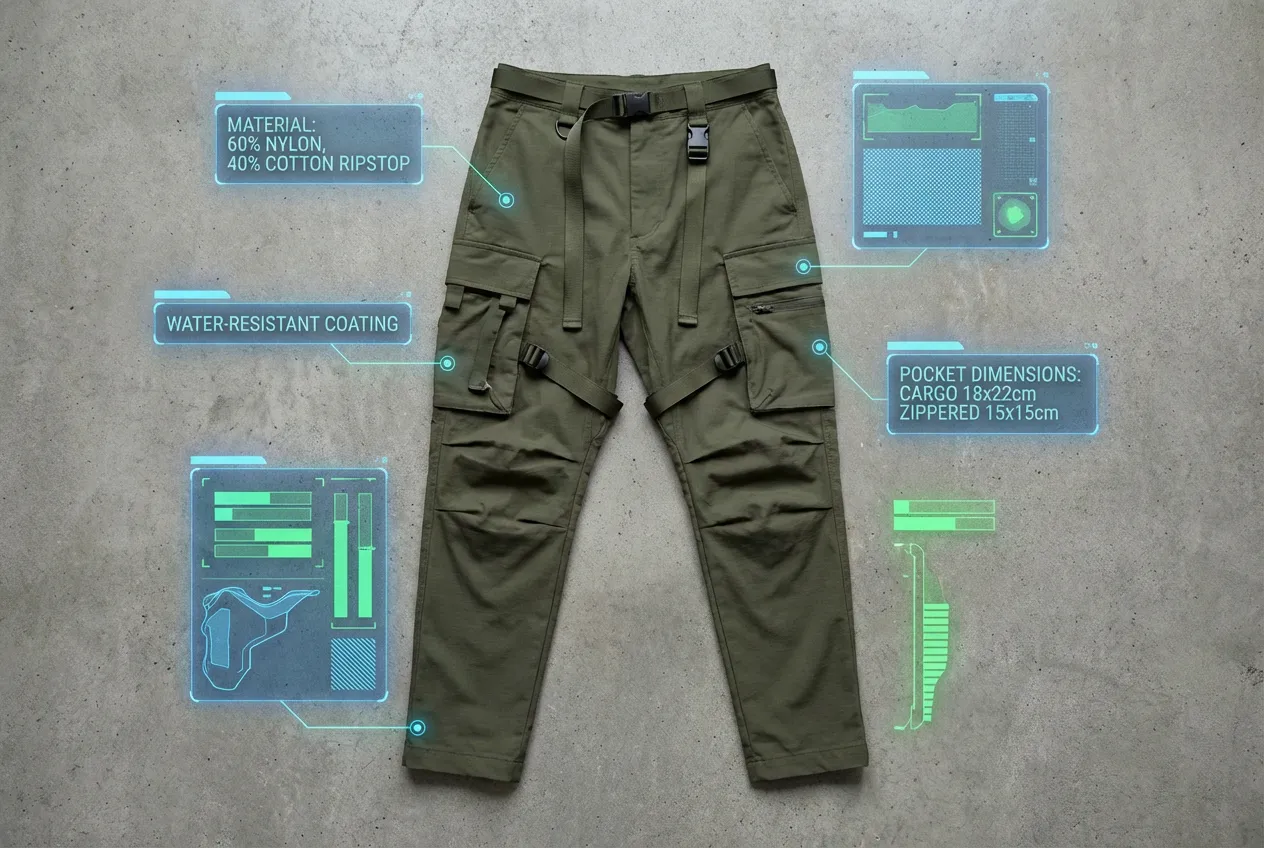

The Tech Pack Solution: Use the Garment Callouts tab to map out the utility. You can drag measurement lines to specify the depth of the pocket pleats and the placement of velcro closures. The Colorways tab is also vital here, as streetwear often drops in multiple color variants; the AI helps you visualize these variants instantly.

Cargo pants with holographic UI elements displaying pocket dimensions.

Cargo pants with holographic UI elements displaying pocket dimensions.

8. Knitwear Cardigans: Yarn & Gauge

Knitwear is unique because you aren't cutting fabric; you are creating it from yarn.

The Challenge: Communicating the density of the knit (Gauge).

The Tech Pack Solution: In the Product Info tab, you define the "Gauge" (e.g., 12GG for fine knit, 5GG for chunky). Unlike cut-and-sew, where you list fabric, in the BOM tab you list "Yarn." The structure of the Adstronaut tech pack adapts to this, allowing you to input yarn composition (e.g., Merino Wool/Acrylic blend) instead of fabric rolls.

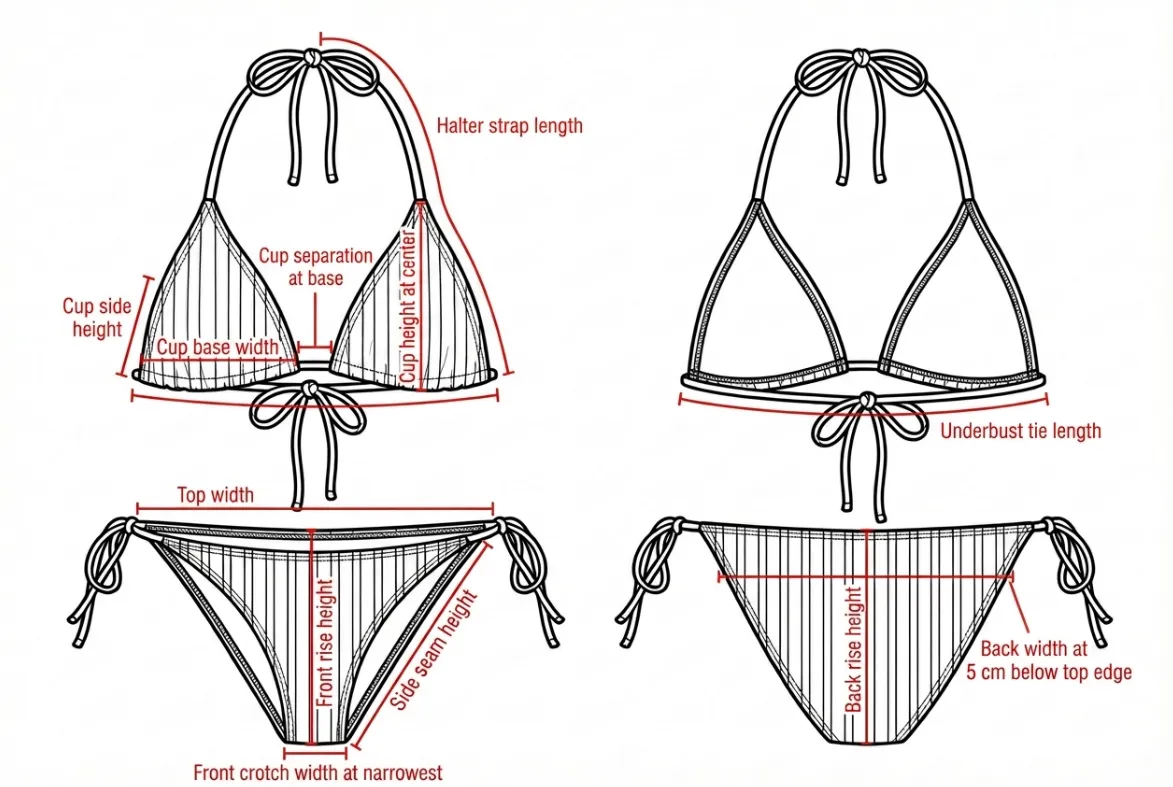

9. Swimwear: Precision & Elasticity

Swimwear has zero margin for error. A quarter-inch difference in a bikini bottom changes the fit from "perfect" to "unwearable."

The Challenge: Extremely precise measurements and specific elastic types.

The Tech Pack Solution: The Sample Measurements tab allows for high-precision inputs. You can click and drag measurement lines on the AI-generated sketch to define the "Leg Opening" and "Crotch Width" down to the millimeter. In the BOM, you would specify "Rubber Elastic" (which resists chlorine) rather than standard elastic.

Interactive sketch editor with precise measurement lines on swimwear.

Interactive sketch editor with precise measurement lines on swimwear.

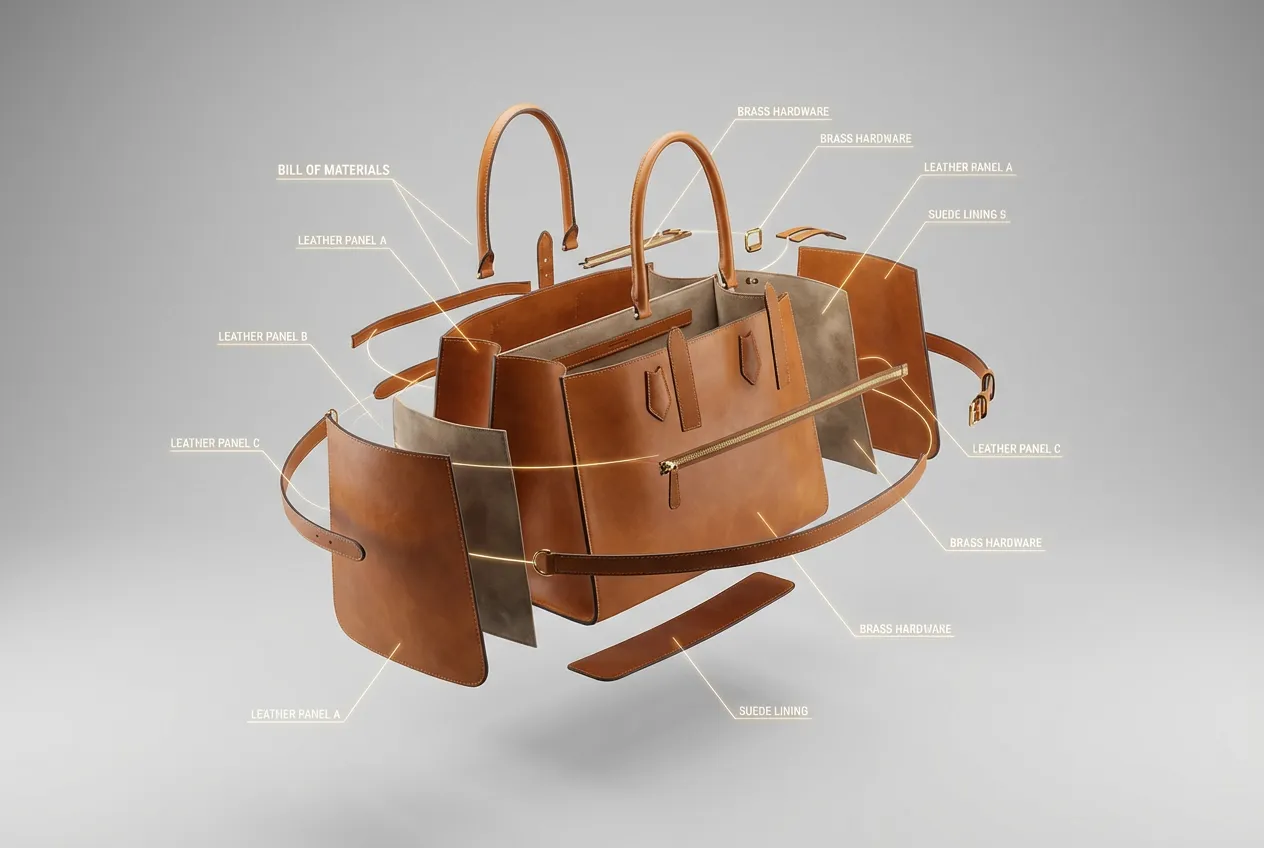

10. Bags & Accessories: Reinforcement

Bags don't have sizing grading, but they have complex reinforcement needs to hold weight.

The Challenge: Showing where the handles are attached and reinforced.

The Tech Pack Solution: The Artwork & Annotation tabs are key. For a tote bag, you use the sketch to draw an "X-Box stitch" diagram at the handle attachment points. This visual instruction tells the factory to reinforce that specific area so the handles don't rip off under heavy loads.

A deconstructed view showing all pattern pieces and reinforcement points.

A deconstructed view showing all pattern pieces and reinforcement points.

Automate Your Tech Pack Structure

No matter what you are designing, the structure of your tech pack dictates the quality of your sample. Manufacturers don't want beautiful illustrations; they want organized data.

Adstronaut AI provides the industry-standard 12-tab framework automatically. It generates the sketches, sets up the tables, and organizes the BOM, saving you the 4-8 hours it typically takes to set up this document structure from scratch.

You provide the creative vision; we provide the factory-ready format. Learn exactly how to create a tech pack step-by-step, or understand the hidden costs you're avoiding by using AI automation.

Start your project and generate a structured tech pack now!