The Complete Guide to Fashion Tech Packs - Everything You Need to Know in 2026

A tech pack (technical package) is a comprehensive blueprint document that tells a manufacturer exactly how to construct your garment. It typically includes flat sketches, a bill of materials (BOM), graded size measurements, construction details, colorway specifications, and packaging instructions. Without one, factories cannot accurately produce your design — and according to industry data, incomplete or missing tech packs are the leading cause of sample rejection, costing brands $500–$50,000+ per error in wasted materials, rework, and production delays.

This guide covers everything you need to know: what a tech pack contains, the 10 essential components every factory expects, how much tech packs cost to create (freelancer vs AI vs in-house), and the most common mistakes that lead to costly production failures.

Table of Contents

- What is a Tech Pack?

- Why Tech Packs Matter: The Cost of Getting It Wrong

- The 10 Essential Components of a Tech Pack

- Who Creates Tech Packs?

- Traditional vs AI-Powered Tech Pack Creation

- Common Tech Pack Mistakes That Cost Thousands

- How to Get Started with Your First Tech Pack

- Frequently Asked Questions

What is a Tech Pack?

A tech pack—short for "technical package"—is a comprehensive document that serves as the blueprint for manufacturing a garment. Think of it as the recipe card for your design. Just as a chef needs exact measurements, ingredients, and cooking instructions to recreate a dish, a manufacturer needs a tech pack to recreate your garment exactly as you envision it.

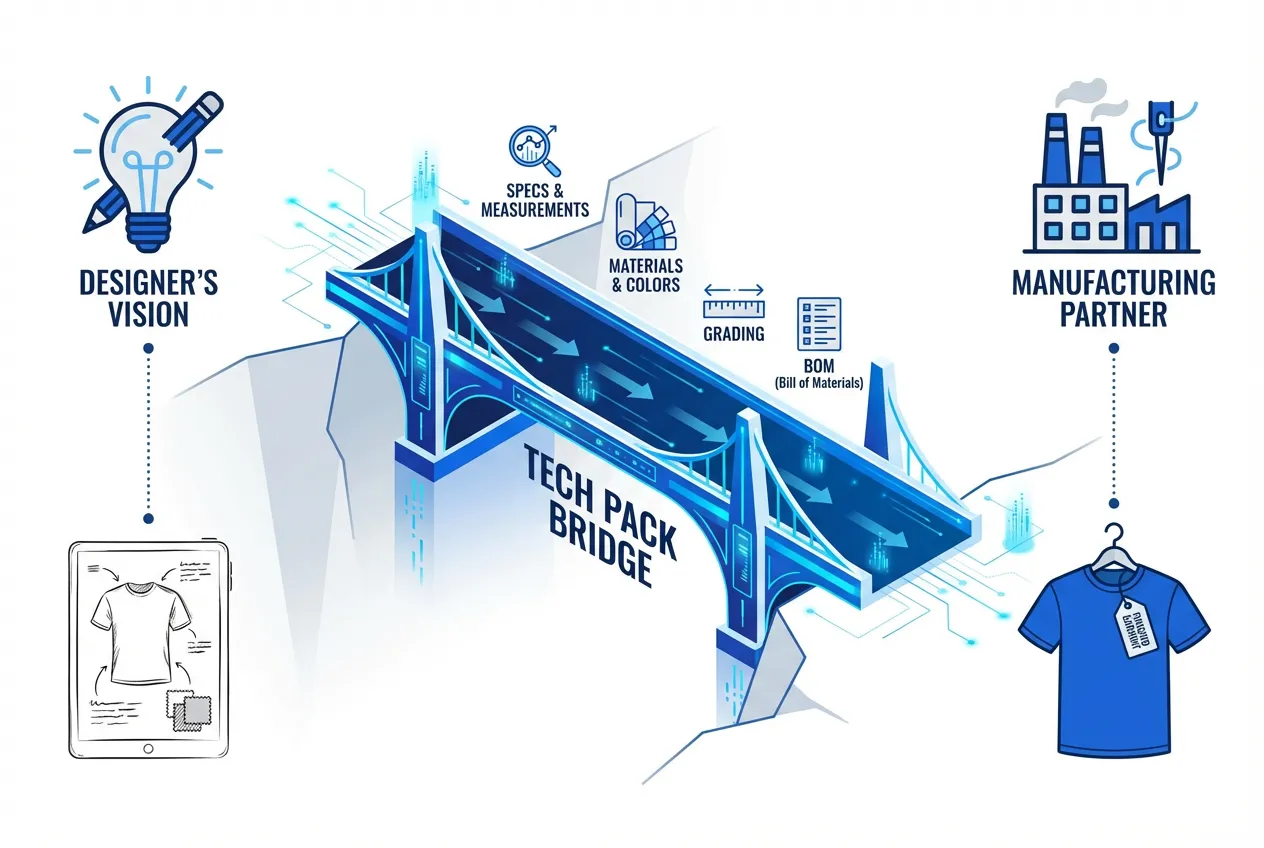

A tech pack bridges the gap between your creative vision and the factory floor.

A tech pack bridges the gap between your creative vision and the factory floor.

A tech pack communicates every single detail about your garment:

- How it should look (flat sketches and design details)

- How it should measure (size specifications)

- What it's made of (materials and components)

- How it should be constructed (sewing instructions)

- What labels and packaging it needs

Without a tech pack, you're essentially asking a manufacturer to read your mind. And as any designer who's received a disastrous first sample can tell you, mind-reading is not a service factories offer.

Why Tech Packs Matter: The Cost of Getting It Wrong

Here's a statistic that should concern every fashion entrepreneur: 5 out of 10 designers approach manufacturers without a proper tech pack. The result? Costly sample revisions, production delays, and garments that don't match the original vision.

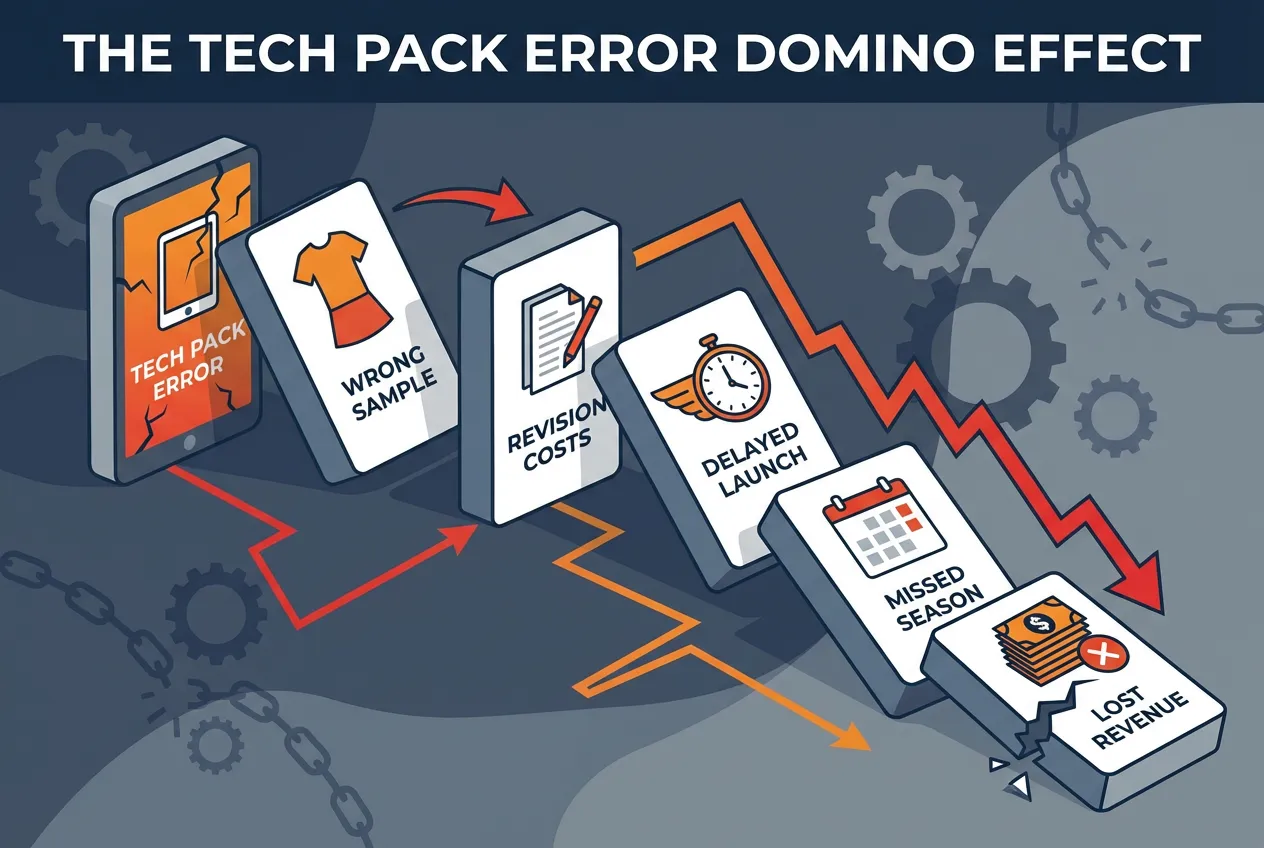

The hidden costs of manual tech packs extend far beyond just the time spent creating them. Consider what happens when your tech pack is incomplete or unclear:

| Problem | Consequence | Typical Cost |

|---|---|---|

| Missing measurement | Wrong fit across all sizes | $500-2,000 per sample round |

| Unclear construction detail | Manufacturer guesses incorrectly | 2-4 week delay + revision costs |

| Wrong material specified | Entire production run uses wrong fabric | $5,000-50,000+ in waste |

| No label placement indicated | Labels sewn in wrong position | Rework costs or rejected inventory |

According to McKinsey's State of Fashion report, supply chain inefficiencies — many of which stem from poor technical documentation — cost the global fashion industry an estimated $500 billion annually. For independent brands, the impact is disproportionately severe: a single miscommunicated spec can consume 20–40% of a startup's seasonal budget.

A professional, complete tech pack eliminates these risks. It ensures everyone—from your pattern maker to your production manager to the factory floor workers—understands exactly what you want.

One tech pack error triggers a costly cascade of problems.

One tech pack error triggers a costly cascade of problems.

The 10 Essential Components of a Tech Pack

A factory-grade tech pack contains several critical components. Here's what manufacturers expect to see:

1. Technical Flat Sketches

Clean, two-dimensional line drawings showing the front and back views of your garment. These aren't fashion illustrations—they're technical drawings that show every seam, stitch, and construction detail with precision.

2. Design Details & Callouts

Zoomed-in views of specific design elements: pocket construction, collar shape, button placement, decorative stitching, or any unique features that require extra clarification.

3. Bill of Materials (BOM)

A complete list of every component needed to make the garment: shell fabric, lining, interfacing, thread, buttons, zippers, labels, hang tags, and packaging materials. Each item includes specifications like fiber content, weight, and color codes.

4. Colorways

All color variations of the design, with exact color references (Pantone codes) for every component. If your t-shirt comes in black, white, and navy, each colorway needs its own specification.

5. Measurement Specifications

A detailed chart showing the exact measurements for every point of measure (POM) across all sizes. This is the foundation of your garment's fit.

6. Size Grading

How measurements change from size to size. For example, if your chest measurement increases by 2 inches between Small and Medium, that grade rule must be documented.

7. Construction Details

Written instructions explaining how the garment should be assembled: seam types, stitch counts per inch, seam allowances, and finishing techniques.

8. Label Placement

Exact positioning for all labels: main label, care label, size label, and any brand tags. Include measurements from reference points.

9. Artwork & Graphics

If your garment includes prints, embroidery, or other graphics, the tech pack must include exact artwork files, placement specifications, and technique requirements.

10. Packaging Instructions

How the finished garment should be folded, tagged, bagged, and packed for shipping.

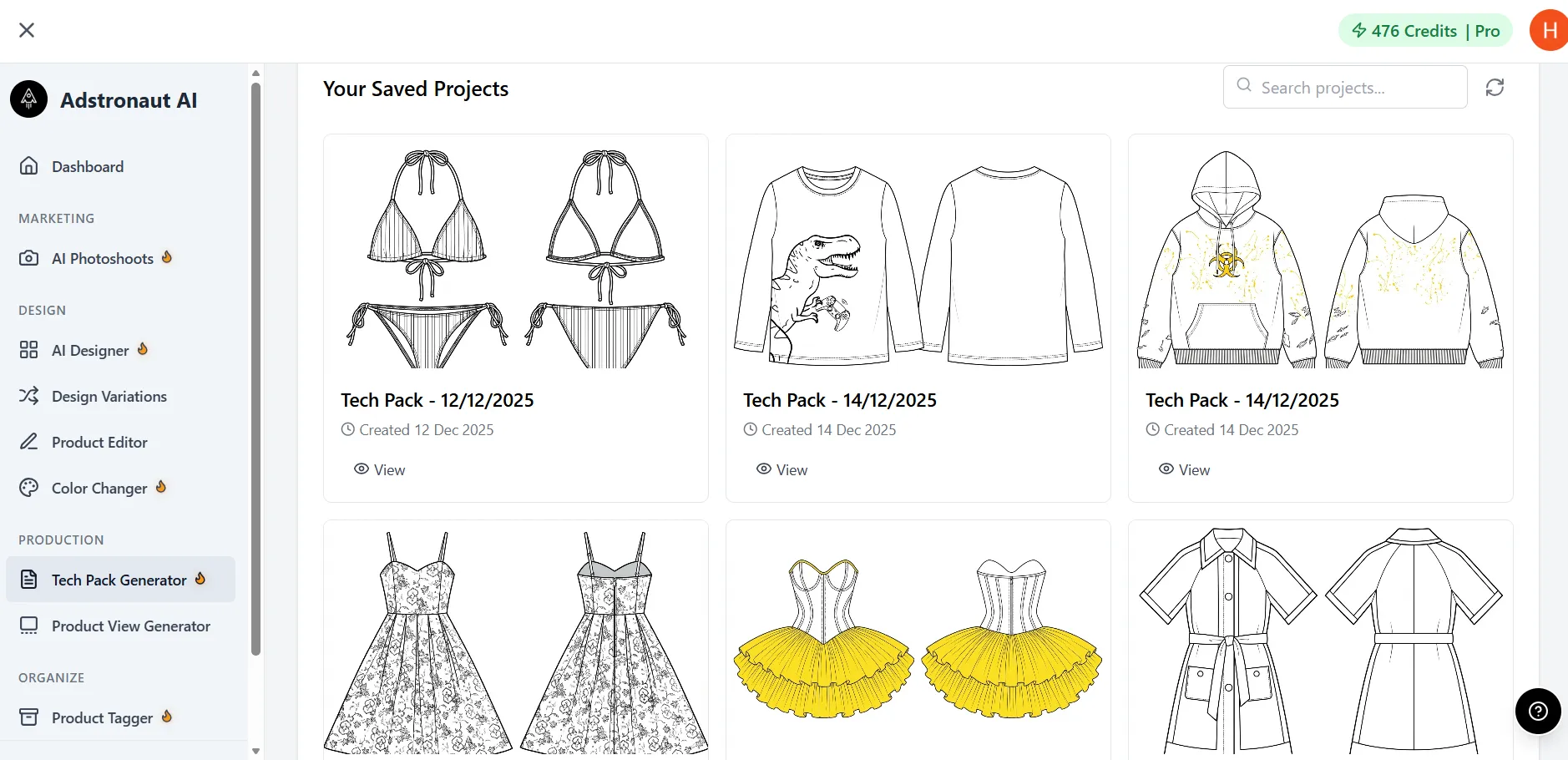

Adstronaut AI generates all 10 components automatically from a single product photo.

Adstronaut AI generates all 10 components automatically from a single product photo.

Who Creates Tech Packs?

Traditionally, tech packs are created by technical designers—specialized professionals who bridge the gap between creative design and manufacturing. They understand both the artistic vision and the technical requirements of production.

For large fashion houses, technical designers are full-time employees. But for independent designers and small brands, options have historically been limited:

Option 1: Learn to do it yourself

- Requires proficiency in Adobe Illustrator

- Steep learning curve (months to years)

- Time-consuming (2-8 hours per style)

Option 2: Hire a freelancer

- Costs $50-$2,000 per style

- Quality varies significantly

- Communication delays add weeks

According to freelance marketplace data, the average tech pack freelancer charges $150–$500 for a standard garment and $500–$2,000+ for complex styles with multiple colorways and detailed construction specs. Turnaround times range from 3–14 business days.

Option 3: Use templates

- Limited flexibility

- Still requires manual data entry

- Doesn't solve the flat sketch problem

This is why so many small brands struggle with tech packs—the traditional options are either too expensive, too time-consuming, or too technically demanding.

Traditional vs AI-Powered Tech Pack Creation

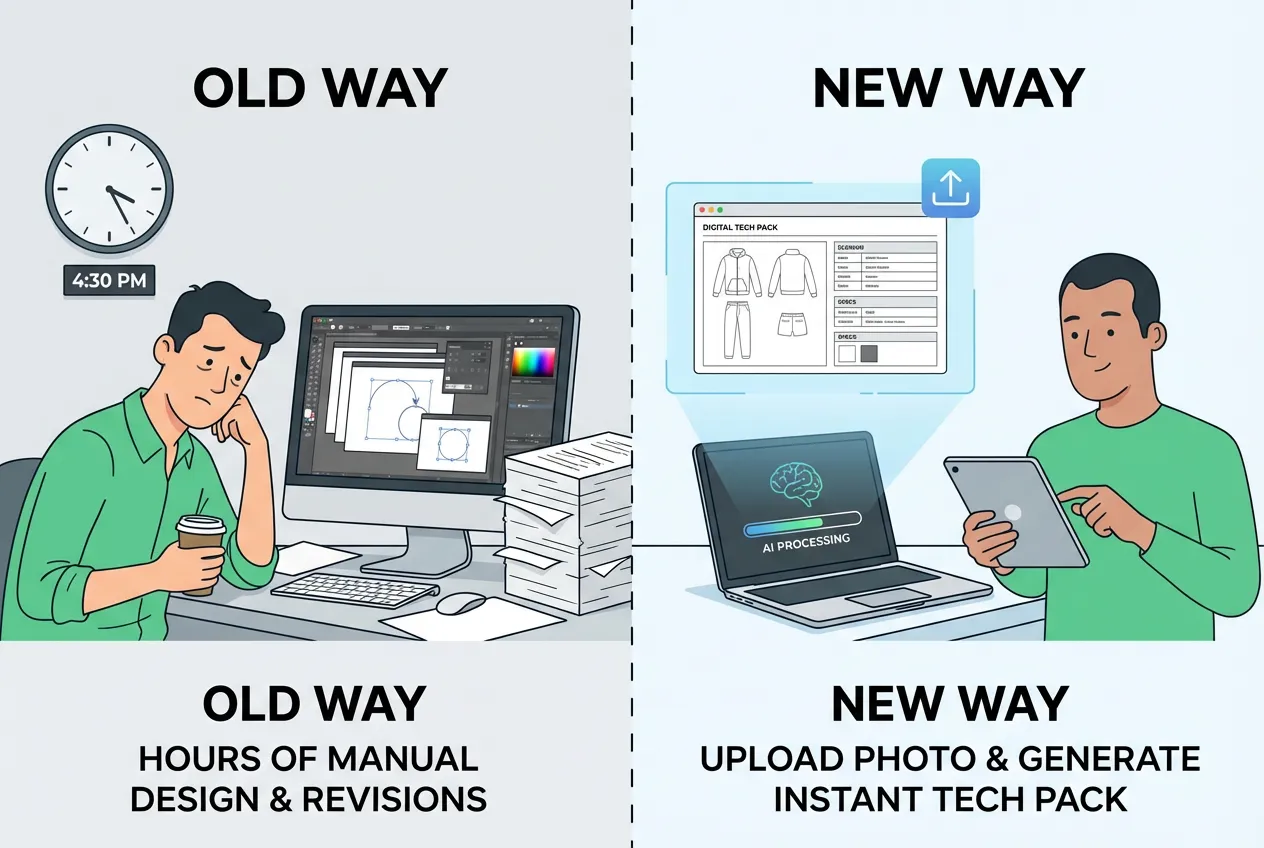

The emergence of AI has fundamentally changed what's possible for independent designers. Tools like Adstronaut AI can now automate tech pack creation, generating factory-grade documents from a single product photo.

| Factor | Traditional Method | AI-Powered Method |

|---|---|---|

| Time per tech pack | 2-8 hours | Under 5 minutes |

| Cost per style | $50-$2,000 (freelancer) | ~$5 |

| Required skills | Illustrator, Excel, technical design | None (just a photo) |

| Consistency | Varies by designer | Standardized every time |

| Revisions | Manual rework | Instant regeneration |

The AI doesn't replace the designer's creative vision—it handles the tedious, technical execution. This human-in-the-loop approach means you review, edit, and approve everything before it goes to your manufacturer.

The old way vs. the new way: hours of manual work replaced by minutes of AI-assisted creation.

The old way vs. the new way: hours of manual work replaced by minutes of AI-assisted creation.

Common Tech Pack Mistakes That Cost Thousands

Even experienced designers make these errors. Avoid them at all costs:

1. Vague Measurements Writing "chest width" without specifying where to measure—armpit to armpit? Across the fullest part? One inch below the armhole? Ambiguity leads to inconsistent sizing.

2. Missing Grade Rules Forgetting to specify how measurements change between sizes. If you only provide measurements for one size, the factory has to guess the rest.

3. Incomplete BOM Forgetting to list the thread color, interfacing type, or label specifications. Every missing component is an opportunity for error.

4. No Reference Points Placing a pocket "roughly in the middle" instead of "4.5 inches from center front, 2 inches below waistband." Precision eliminates guesswork.

5. Outdated Information Using an old version of your tech pack after making design changes. Version control is critical.

How to Get Started with Your First Tech Pack

Ready to create your first tech pack? Here's a practical roadmap:

Step 1: Gather Your Materials Before you start, have ready:

- Clear photos of your garment (or sample)

- Size chart for your target market

- Material swatches or specifications

- Any artwork files for prints/graphics

Step 2: Choose Your Method Decide how you'll create the tech pack:

- Manual (Illustrator + Excel)

- Freelancer

- AI-powered tool like Adstronaut AI

Step 3: Start with the Flat Sketch The technical drawing is the foundation. Everything else builds from this visual reference.

Step 4: Add Measurements Systematically Work through every point of measure. Don't skip any—factories will ask for missing information anyway.

Step 5: Complete the BOM List every single component. When in doubt, include it.

Step 6: Document Construction Write clear, specific instructions. Assume the reader has never seen your design before.

Step 7: Review and Verify Check every detail. Have someone else review it. Errors caught now are infinitely cheaper than errors caught during production.

For most designers, AI-powered tools offer the fastest path from idea to factory-ready documentation. You can create your first tech pack in minutes, then focus your energy on what matters most: designing great products.

For specific garment guides, check out our detailed tutorials on T-shirt tech packs, hoodie tech packs, and dress tech packs. Want to see real examples? Browse our tech pack examples gallery.

The tech pack might not be the most glamorous part of fashion, but it's arguably the most important. It's the document that transforms your creative vision into a manufactured reality. Whether you create yours manually, hire a freelancer, or leverage AI tools, investing in a professional tech pack is investing in your brand's success.

Ready to streamline your entire production workflow? Explore how tech packs integrate with AI photoshoots and automated product tagging to transform your design-to-delivery process. Calculate your potential savings with our ROI calculator.

Frequently Asked Questions

What is a tech pack in fashion?

A tech pack (technical package) is a detailed document that serves as the blueprint for manufacturing a garment. It contains flat sketches, measurements, materials lists, construction instructions, and all specifications a factory needs to produce your design accurately. Think of it as the "recipe" that ensures every unit matches your original vision.

How much does a tech pack cost?

Tech pack costs vary significantly by method. Hiring a freelance technical designer typically costs $150–$500 for simple garments (t-shirts, basic dresses) and $500–$2,000+ for complex styles. In-house technical designers at large brands earn $55,000–$85,000 annually. AI-powered tools like Adstronaut AI can generate a complete tech pack for approximately $3–$5 per style in under 5 minutes.

Can I create a tech pack without Adobe Illustrator?

Yes. While Adobe Illustrator has been the traditional industry standard for creating flat sketches and tech pack layouts, modern alternatives exist. AI-powered tools can generate technical flat sketches from product photos, eliminating the need for Illustrator entirely. Some designers also use free alternatives like Inkscape, or template-based tools like Techpacker.

What is the difference between a tech pack and a spec sheet?

A spec sheet (specification sheet) is one component of a tech pack — it contains the garment's measurements and size grading. A tech pack is the complete document that includes the spec sheet plus flat sketches, bill of materials, construction details, colorways, label placement, and packaging instructions. Factories need the full tech pack, not just a spec sheet.

How many pages should a tech pack be?

A standard tech pack ranges from 6–15 pages depending on garment complexity. A basic t-shirt tech pack might be 6–8 pages, while a tailored blazer or technical outerwear piece could require 12–15+ pages. The key is completeness — every page should contain information the factory needs to produce the garment correctly.

Do I need a tech pack for every style in my collection?

Yes. Every unique style requires its own tech pack. However, colorway variations of the same style can share a single tech pack with a colorway page showing each color option. For example, if you have one t-shirt design in 5 colors, you need one tech pack with 5 colorway specifications, not 5 separate tech packs.

What file format should a tech pack be in?

Most factories prefer tech packs as PDF files for easy viewing and printing. However, the working document is typically created in Adobe Illustrator (.ai), Excel (.xlsx), or specialized tech pack software. AI tools like Adstronaut export directly to PDF. Always confirm your factory's preferred format before sending — some factories in Asia prefer Excel-based formats.

What happens if I send a garment to production without a tech pack?

Without a tech pack, the factory will interpret your design based on a reference photo or sample alone, making assumptions about measurements, materials, construction methods, and finishing details. Industry data shows this leads to an average of 3–5 sample revision rounds (vs. 1–2 with a proper tech pack), adding 6–12 weeks and $1,500–$5,000+ to your development costs per style.

Create your first tech pack in minutes — free to try!

Sources and further reading:

- McKinsey & Company — The State of Fashion (annual industry report on supply chain costs and inefficiencies)

- Common Objective — Fashion Production: The Hidden Costs (research on sampling waste in fashion supply chains)

- ASTM International — Standard Tables of Body Measurements (measurement standards referenced in tech pack grading)

- Maker's Row — The Complete Guide to Working with Manufacturers (factory communication and tech pack best practices)