How to Grade Sizes for a Clothing Line — Measurement Charts & Formulas

Size grading is the process of scaling a base-size garment pattern up and down to create a full size range (typically XS through 3XL). The standard grade rule for most garment measurements is 1-2 inches (2.5-5 cm) between sizes: chest width grades 1.5-2 inches per size, body length grades 1-1.5 inches, and sleeve length grades 0.5-1 inch. Grading starts from your "base size" (usually Medium for women's and Large for men's) and applies these increments symmetrically up and down.

This guide provides the actual measurement tables, grade rules by garment type, plus-size adjustments, and step-by-step instructions to build your own size chart from scratch. Whether you are launching your first collection or refining an existing line, these reference charts will save you weeks of trial and error. Need a primer on tech packs first? Start with our complete guide to fashion tech packs.

Table of Contents

- What Is Size Grading?

- Standard Grade Rules by Measurement Point

- Grade Rules by Garment Type

- Plus-Size Grading (XL and Above)

- How to Create Your Own Size Chart

- Common Grading Mistakes

- How Tech Packs Handle Grading

- Frequently Asked Questions

- Sources

Pattern maker measuring a garment on a cutting table with measuring tape, grading ruler, and printed size chart

Pattern maker measuring a garment on a cutting table with measuring tape, grading ruler, and printed size chart

What Is Size Grading?

Size grading (also called "pattern grading" or "nest grading") is the systematic process of increasing or decreasing a base-size pattern at specific measurement points to produce a complete size range. Rather than creating a brand-new pattern for every size, you design and perfect one base size, then mathematically scale it using predetermined "grade rules" — the exact inch or centimeter increment applied at each point of measure (POM).

Why grading matters financially: Incorrect grading is one of the most expensive mistakes in garment manufacturing. According to industry data from Maker's Row, a single grading error can cost a brand $2,000-$10,000 in remake costs per style once multiplied across the full size run (Maker's Row, 2024). If your Medium fits perfectly but your Large chest is 3 inches wider instead of 2, every Large garment in that production run ships with the wrong fit.

The stakes go beyond production costs. A 2023 report by the American Apparel & Footwear Association (AAFA) found that fit-related issues account for 52% of online apparel returns, and brands with inconsistent sizing across their range see return rates 30-40% higher than brands with well-graded size charts (AAFA, 2023). For a brand doing $500,000 in annual revenue, that gap in return rates translates to $150,000-$200,000 in lost margin.

Standard Grade Rules by Measurement Point

Grade rules vary by measurement point because the human body does not scale uniformly. The chest expands more per size than the neck, and the inseam barely changes at all. Below are industry-standard grade rules based on ASTM D5585 (women's) and ASTM D6240 (men's) body measurement standards.

Women's Tops — Full Grade Chart (XS through 3XL)

All measurements in inches. Base size: M (Medium).

| Measurement Point | XS | S | M (Base) | L | XL | 2XL | 3XL | Grade per Size |

|---|---|---|---|---|---|---|---|---|

| Chest Width (1/2) | 17 | 18.5 | 20 | 21.5 | 23 | 25 | 27 | +1.5" (XS-XL) / +2" (XL+) |

| Waist Width (1/2) | 14.5 | 16 | 17.5 | 19 | 20.5 | 22.5 | 24.5 | +1.5" (XS-XL) / +2" (XL+) |

| Hip Width (1/2) | 18 | 19.5 | 21 | 22.5 | 24 | 26 | 28 | +1.5" (XS-XL) / +2" (XL+) |

| Body Length (HPS) | 25 | 25.75 | 26.5 | 27.5 | 28.5 | 29.5 | 30.5 | +1" |

| Sleeve Length | 7.25 | 7.75 | 8.25 | 9 | 9.75 | 10.5 | 11.25 | +0.75" |

| Across Shoulder | 14 | 14.75 | 15.5 | 16.25 | 17 | 17.75 | 18.5 | +0.75" |

| Neck Width (1/2) | 7 | 7.25 | 7.5 | 7.75 | 8 | 8.25 | 8.5 | +0.25" |

| Armhole Depth | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 | 10.5 | +0.5" |

Note: Half-measurements (1/2) are measured flat across one side of the garment. Double for full circumference.

Men's Tops — Full Grade Chart (XS through 3XL)

All measurements in inches. Base size: L (Large).

| Measurement Point | XS | S | M | L (Base) | XL | 2XL | 3XL | Grade per Size |

|---|---|---|---|---|---|---|---|---|

| Chest Width (1/2) | 19 | 21 | 23 | 25 | 27 | 29.5 | 32 | +2" (XS-XL) / +2.5" (XL+) |

| Waist Width (1/2) | 17 | 19 | 21 | 23 | 25 | 27.5 | 30 | +2" (XS-XL) / +2.5" (XL+) |

| Hip Width (1/2) | 19 | 21 | 23 | 25 | 27 | 29.5 | 32 | +2" (XS-XL) / +2.5" (XL+) |

| Body Length (HPS) | 27 | 28 | 29 | 30 | 31 | 32.5 | 34 | +1.5" |

| Sleeve Length | 8 | 8.5 | 9 | 9.5 | 10 | 10.5 | 11 | +0.5"-1" |

| Across Shoulder | 16 | 17 | 18 | 19 | 20 | 21 | 22 | +1" |

| Neck Width (1/2) | 7 | 7.25 | 7.5 | 7.75 | 8 | 8.5 | 9 | +0.25"-0.5" |

| Armhole Depth | 8 | 8.75 | 9.5 | 10.25 | 11 | 11.75 | 12.5 | +0.75" |

Bottoms (Unisex) — Full Grade Chart (XS through 3XL)

All measurements in inches. Base size: M (Medium).

| Measurement Point | XS | S | M (Base) | L | XL | 2XL | 3XL | Grade per Size |

|---|---|---|---|---|---|---|---|---|

| Waist Width (1/2) | 13 | 14.5 | 16 | 17.5 | 19 | 21 | 23 | +1.5" (XS-XL) / +2" (XL+) |

| Hip Width (1/2) | 17.5 | 19 | 20.5 | 22 | 23.5 | 25.5 | 27.5 | +1.5" (XS-XL) / +2" (XL+) |

| Front Rise | 9.5 | 10 | 10.5 | 11 | 11.5 | 12 | 12.5 | +0.5" |

| Back Rise | 13 | 13.5 | 14 | 14.5 | 15 | 15.75 | 16.5 | +0.5"-0.75" |

| Inseam | 31 | 31 | 31 | 31 | 31 | 31 | 31 | 0" (no grade) |

| Outseam | 40 | 40.5 | 41 | 41.5 | 42 | 42.75 | 43.5 | +0.5"-0.75" |

| Thigh Width (1/2) | 10 | 11 | 12 | 13 | 14 | 15 | 16 | +1" |

| Knee Width (1/2) | 7 | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 | +0.5" |

| Leg Opening (1/2) | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | 9 | +0.5" |

Key insight on inseam: The inseam does not grade between sizes because leg length is independent of body width. A size S person and a size XL person can have the same leg length. Inseam variation is handled through separate length options (Short, Regular, Long) rather than through size grading.

Grade Rules by Garment Type

While the charts above provide baseline rules, specific garment types require adjustments. According to data published by the Textile/Clothing Technology Corporation (TC2), garment fit satisfaction varies by up to 23% depending on whether garment-specific grade rules are applied versus generic ones (TC2, 2022).

T-Shirts and Casual Tops

T-shirts use the most forgiving grade rules because the relaxed fit absorbs minor inconsistencies. Standard grade: chest +1.5"-2", body length +1", sleeve +0.75". The oversized trend has pushed many brands to use the higher end of these ranges. For a complete breakdown, see our t-shirt tech pack guide.

Dress Shirts and Button-Downs

Dress shirts demand tighter grading because they are worn closer to the body. Chest grades +1.5" (not 2"), and the neck is graded at +0.5" per full size. Collar and cuff measurements must grade in sync — a common error is grading the body correctly but forgetting that sleeve cuff circumference also needs to increase by 0.25-0.5" per size.

Pants and Jeans

As shown in the bottoms chart above, pants are unique because the inseam does not grade. The waist and hip are the primary grade points at +1.5" per size. Thigh width grades at +1" per size, but the knee and leg opening grade at only +0.5" to maintain the silhouette. Rise (both front and back) grades at +0.5" per size to accommodate the changing seat depth across sizes.

Dresses and Skirts

Dresses require compound grading because they span the bust, waist, and hip — three zones that grade at different rates. Bust and hip typically grade at +1.5", but the waist may grade at +1.5" to +2" depending on the silhouette. Dress length grades at +1" per size from the waist down. A-line and fit-and-flare styles require more hip grade (+2") to maintain the intended proportional flare. For more, see our dress tech pack guide.

Outerwear and Jackets

Outerwear uses larger grade rules than the underlying garment to maintain consistent layering room across sizes. The industry standard is to add +0.5" to the standard grade at chest and hip — so if a t-shirt grades at +2", a jacket grades at +2.5". Sleeve length also grades more aggressively (+1" instead of +0.75") because outerwear sleeves must fully cover the sleeves of garments underneath. According to the AAFA technical guidelines, failing to account for layering ease is the number-one cause of poor outerwear fit across sizes (AAFA, 2023).

Plus-Size Grading (XL and Above)

One of the most common and costly grading mistakes is applying the same grade rule across the entire size range. Above XL, grade rules must increase. This is because the human body does not scale linearly — larger bodies carry proportionally more width relative to height.

The ASTM D5585 standard (Standard Table of Body Measurements for Adult Female Misses Figure Type, Sizes 2-20) documents that body circumference increases accelerate above a size 16, which corresponds roughly to XL in letter sizing (ASTM International, 2023). The companion standard ASTM D6240 (Standard Tables of Body Measurements for Men Sizes Thirty-Four to Sixty) shows the same non-linear pattern in men's measurements.

How grade rules change for plus sizes:

| Measurement Point | Standard Grade (XS-XL) | Plus-Size Grade (XL-3XL) | Increase |

|---|---|---|---|

| Chest (women's) | +1.5" per size | +2" per size | +0.5" |

| Chest (men's) | +2" per size | +2.5" per size | +0.5" |

| Waist (women's) | +1.5" per size | +2" per size | +0.5" |

| Waist (men's) | +2" per size | +2.5" per size | +0.5" |

| Hip (women's) | +1.5" per size | +2" per size | +0.5" |

| Body Length | +1" per size | +1"-1.5" per size | +0"-0.5" |

| Armhole Depth | +0.5" per size | +0.5"-0.75" per size | +0"-0.25" |

Why this matters commercially: Research from Coresight Research estimates that the US plus-size apparel market reached $39.5 billion in 2024, growing at 5.2% annually — faster than the overall apparel market at 2.8% (Coresight Research, 2024). Brands that skip proper plus-size grading lose this customer permanently. A 2XL customer who buys a poorly graded garment that fits like a tight XL will not return for a second purchase.

The practical impact: if you are grading a women's top and your Medium chest (base) is 20" (half-measurement), your progression should be: XL = 23" (+1.5" per size from M), 2XL = 25" (+2"), 3XL = 27" (+2"). Not XL = 23", 2XL = 24.5", 3XL = 26" — which would be the result of applying the standard 1.5" grade through the plus range.

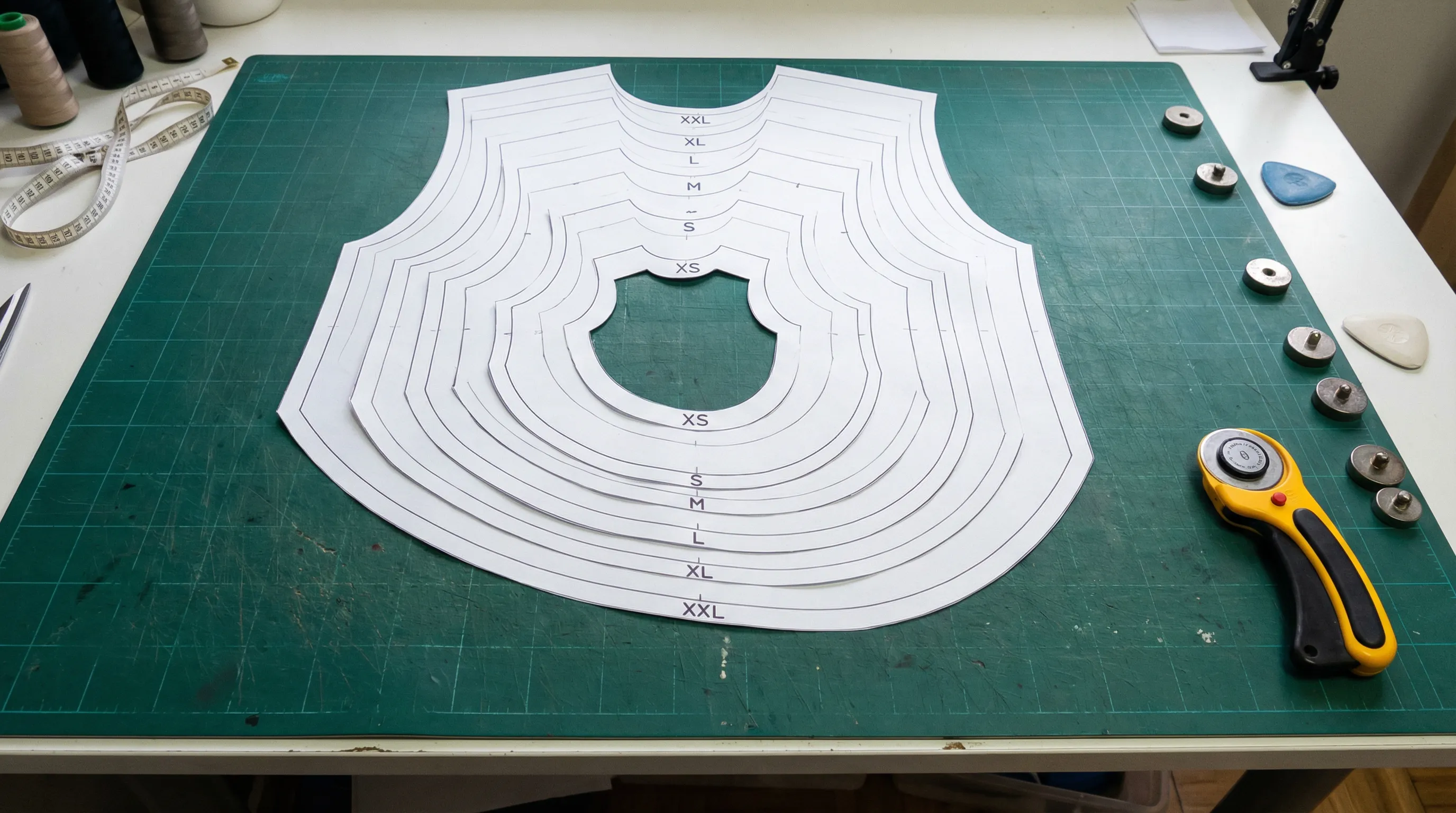

Nested clothing patterns in sizes XS through XXL laid out on a cutting table showing progressive size scaling

Nested clothing patterns in sizes XS through XXL laid out on a cutting table showing progressive size scaling

How to Create Your Own Size Chart

Follow these six steps to build a production-ready graded size chart for any garment.

Step 1: Choose Your Target Market and Fit Preference

Your grade rules depend on who you are designing for and how you want the garment to fit. A streetwear brand targeting 18-25-year-olds may want a relaxed, oversized fit (add +1" of ease to standard chest grades). An athleisure brand may want a body-hugging fit (subtract 0.5" from standard grades). Define this before you pick up a tape measure.

Step 2: Select a Base Size

The base size is the size you will design, pattern, and sample first. All other sizes are derived from it.

- Women's: Medium (size 8-10) is the most common base size

- Men's: Large (size 40-42 chest) is standard

- Children's: Varies by age group; typically the middle of the range

Choose the base size that represents your core customer. According to AAFA data, the average American woman wears a size 16-18 (L-XL in letter sizing), so some inclusive brands now use L or XL as their base size and grade down as well as up (AAFA, 2023).

Step 3: Create a Sample in the Base Size

Produce a physical sample in your base size. Fit it on a live fit model (not just a dress form) whose measurements match your target body for that size. Document every measurement with a tolerance of +/- 0.25" for knits and +/- 0.125" for wovens.

Step 4: Apply Grade Rules

Using the measurement tables from the earlier sections, apply the appropriate grade rule at each point of measure. Work outward from your base in both directions (up to 3XL, down to XS). Remember:

- Different measurement points grade at different rates

- Plus sizes (above XL) use increased grade rules

- Inseams do not grade

- Decorative elements (pocket placement, logo position) also need to be graded proportionally

Step 5: Test-Fit Across Sizes

Produce samples in at least three sizes: your base, one small (S or XS), and one large (XL or 2XL). Fit each on an appropriate fit model. Common issues that emerge at this stage include:

- Shoulder seams drifting off the shoulder point in smaller sizes

- Armholes becoming too tight in larger sizes

- Proportional imbalance (a Large that looks like a "bigger Medium" instead of a garment designed for a larger body)

Step 6: Adjust and Finalize

Based on fit-session feedback, adjust specific grade rules. It is normal to revise 2-3 measurement points after the first round of fitting. Lock in your final graded spec table and add it to your tech pack. This table becomes the contractual measurement standard between you and your manufacturer.

Common Grading Mistakes

Mistake 1: Grading All Points Equally

The most frequent error. Beginners apply the same grade (e.g., +1.5") to chest, waist, hip, neck, and sleeve. In reality, the neck only grades +0.25" per size while the chest grades +1.5-2". Applying a 1.5" grade to the neck would produce a comically wide neckline by size XL.

Mistake 2: Ignoring Ease

Ease is the difference between body measurement and garment measurement. A chest that measures 40" on the body needs a garment chest of 42-46" depending on the intended fit. When grading, you are grading the garment measurements, not body measurements. The ease should remain consistent across all sizes — if your Medium has 3" of ease at the chest, your 2XL should also have approximately 3" of ease.

Mistake 3: Not Adjusting for Plus Sizes

As covered in the plus-size section, applying standard grade rules above XL results in garments that are increasingly too tight. This single mistake is responsible for the majority of fit complaints in extended-size ranges.

Mistake 4: Inconsistent Tolerances

A tolerance is the acceptable range around each measurement (e.g., chest width 20" +/- 0.5"). Tolerances must be defined for every measurement and every size. Without them, your factory has no quality control benchmark. Industry standard tolerances are:

- Critical measurements (chest, waist): +/- 0.5" for knits, +/- 0.25" for wovens

- Secondary measurements (sleeve length, body length): +/- 0.5"

- Minor measurements (pocket placement): +/- 0.25"

Mistake 5: Forgetting to Grade Design Elements

Pocket width, logo placement height, yoke depth, and other design details also need proportional grading. A pocket that looks balanced on a Medium can look undersized on a 2XL if it was not graded.

How Tech Packs Handle Grading

The graded measurement table is one of the most critical pages in any tech pack. It is, in effect, the grading specification itself. When a factory receives your tech pack, the measurement table tells them the exact finished dimensions for every size, and the tolerance column tells them the acceptable variance.

A well-structured tech pack measurement page includes:

- A Point of Measure (POM) diagram — a flat sketch with numbered callout lines showing where each measurement is taken

- The graded spec table — all sizes in columns, all measurement points in rows, with the base size highlighted

- A tolerance column — the allowable +/- for each measurement

- Measurement method notes — whether a measurement is taken flat (half-measurement) or full circumference, relaxed or stretched

This is exactly the structure that Adstronaut's AI tech pack generator produces automatically. When you upload a garment image, the system classifies the garment type, applies the appropriate grade rules from its database, and generates the full spec table across your chosen size range. You can adjust any individual measurement before exporting.

For a walkthrough of how to read and interpret these tables, see our guide on what is a tech pack.

Fashion designer fitting a muslin garment on an adjustable dress form with measurement annotations and measuring tape

Fashion designer fitting a muslin garment on an adjustable dress form with measurement annotations and measuring tape

Frequently Asked Questions

What is the standard grade rule for t-shirts?

The standard grade rule for t-shirts is +1.5" to +2" at the chest per size, +1" for body length, and +0.75" for sleeve length. T-shirts are the most forgiving garment for grading because the relaxed fit hides minor inconsistencies. For a detailed breakdown of t-shirt measurements, see our t-shirt tech pack guide.

How do I grade plus sizes?

Above XL, you must increase your grade rule by 0.5" at the primary circumference points (chest, waist, hip). So if your standard grade is +1.5" at the chest from XS to XL, it becomes +2" from XL to 2XL and from 2XL to 3XL. This accounts for the non-linear way the human body scales at larger sizes, as documented in ASTM D5585.

What base size should I start with?

For women's apparel, the most common base size is Medium (size 8-10). For men's, it is Large (size 40-42 chest). However, if your brand focuses on plus-size or inclusive sizing, consider using L or XL as your base to ensure the best fit for your core customer. The base size is where you invest the most fit development time.

Do I need to grade every measurement point?

Yes, technically every measurement point on a garment should have a grade rule assigned — but not all points grade at the same rate, and some do not grade at all. The inseam on pants, for example, remains constant across sizes. Neck width grades at only +0.25" per size. A complete tech pack spec table assigns a specific grade increment (which can be zero) to every POM.

What is the difference between grading and sizing?

Sizing is the system of size labels you assign (XS, S, M, L, XL or 0, 2, 4, 6, 8, etc.). Grading is the mathematical process of adjusting pattern measurements between those sizes. You can have a sizing system without doing any grading (simply assigning sizes arbitrarily), but you cannot have consistent, well-fitting garments across a size range without proper grading. Grading is the engineering underneath the sizing labels.

Can AI help with size grading?

Yes. AI-powered tech pack tools like Adstronaut can automatically apply industry-standard grade rules based on garment type, generate full spec tables across your size range, and flag potential grading errors (such as a neck grade that is too aggressive or missing plus-size adjustments). This reduces the time from hours of manual spreadsheet work to minutes, while minimizing human calculation errors.

What is nested grading?

Nested grading refers to the practice of overlaying all graded pattern pieces on a single sheet to visualize the proportional scaling across sizes. When you look at a nested grade, you see the smallest size on the inside and the largest on the outside, with all other sizes layered in between. This visual tool helps pattern makers spot grading errors — if the spacing between sizes is uneven, or if a specific area scales disproportionately, it is immediately visible in the nest. Most CAD software (Gerber, Optitex, Lectra) generates nested grades automatically.

How do I handle petite or tall sizing?

Petite and tall sizing adjust length measurements only while keeping circumference grades unchanged. The industry standard adjustments are:

- Petite: Subtract 1.5-2" from body length, 1" from sleeve length, and 2" from inseam (for pants) compared to the regular size

- Tall: Add 1.5-2" to body length, 1" to sleeve length, and 2" to inseam compared to the regular size

Chest, waist, and hip measurements remain the same as their regular-size counterparts. A Petite Medium has the same circumference as a Regular Medium, just shorter in all vertical dimensions.

Sources

- ASTM D5585-11(2023) — Standard Table of Body Measurements for Adult Female Misses Figure Type, Sizes 2-20. ASTM International. astm.org

- ASTM D6240-18(2023) — Standard Tables of Body Measurements for Men Sizes Thirty-Four to Sixty. ASTM International. astm.org

- American Apparel & Footwear Association (AAFA) — ApparelStats and ShoeStats Annual Reports, 2023. aafaglobal.org

- Maker's Row — "The True Cost of Garment Grading Errors," 2024. makersrow.com

- Coresight Research — "US Plus-Size Apparel Market Report," 2024. coresight.com

- Textile/Clothing Technology Corporation (TC2) — "Garment Fit and Sizing Research," 2022. tc2.com