Jacket Tech Pack — Outerwear Manufacturing Specs Guide

A jacket tech pack is a 10–15 page technical document that specifies shell fabric, lining material, insulation type and weight (if applicable), closure system (zipper gauge, snap type, button specifications), pocket construction (welt, patch, zippered, interior), collar/hood details, and graded measurements with extra ease for layering. Jackets and outerwear are the most complex garments to spec — a single bomber jacket can have 30+ individual components compared to 8–10 for a t-shirt — making the tech pack essential for accurate first samples.

This guide covers every component of a factory-ready jacket tech pack, from shell and lining BOMs to insulation specs and hardware callouts. It is the most detailed garment-specific tech pack reference we publish. New to tech packs? Start with our complete guide to fashion tech packs.

Table of Contents

- What Is a Jacket Tech Pack?

- Key Components of a Jacket Tech Pack

- 1. Flat Sketch (Front, Back, Interior)

- 2. Shell & Lining BOM

- 3. Insulation Specifications

- 4. Closure & Hardware

- 5. Pocket Construction

- 6. Collar & Hood Details

- 7. Measurements & Grading

- 8. Construction Details

- Jacket Types & Their Unique Specs

- Common Jacket Tech Pack Mistakes

- Create Your Jacket Tech Pack in Minutes

- Frequently Asked Questions

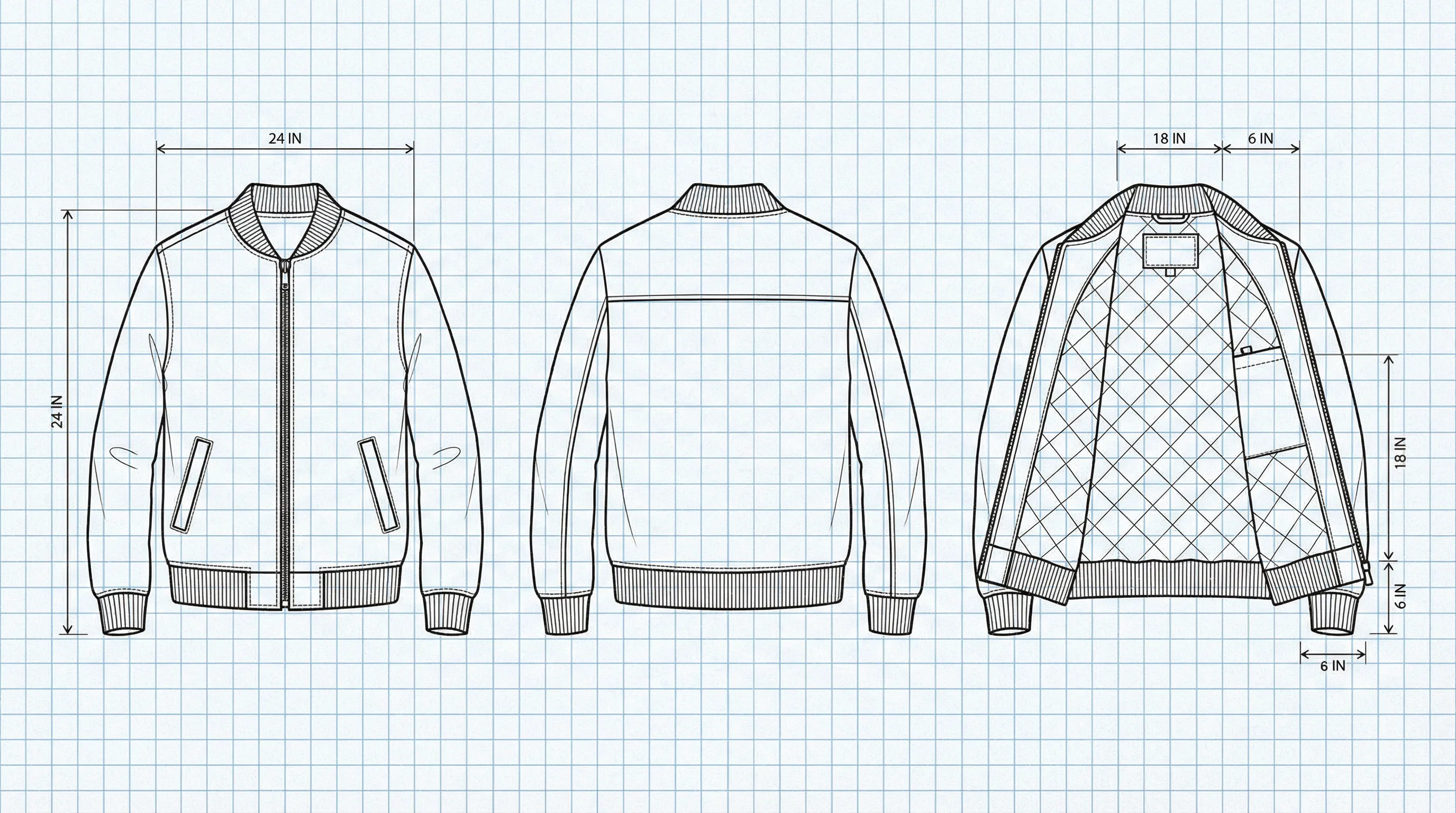

Technical flat sketch of a bomber jacket on blueprint paper showing front view, back view, and interior lining detail with measurement annotations

Technical flat sketch of a bomber jacket on blueprint paper showing front view, back view, and interior lining detail with measurement annotations

What Is a Jacket Tech Pack?

A jacket tech pack is the manufacturing blueprint for any outerwear garment — bombers, parkas, puffers, denim jackets, rain shells, and structured blazers. While a t-shirt tech pack can fit on 6–8 pages and a hoodie tech pack needs around 8–10, a jacket tech pack typically runs 10–15 pages because of the sheer number of components, fabric layers, and hardware involved.

According to Allied Market Research, the global outerwear market was valued at over $230 billion in 2024 and is projected to reach $340 billion by 2032, representing roughly 20–25% of the total apparel market by value. That market share reflects the complexity and cost density of outerwear — and the reason manufacturers demand exceptionally detailed specs before cutting a single pattern piece.

Why jackets need more detail than any other garment:

- Multiple fabric layers: Shell, lining, interlining, and insulation each need separate specs.

- Hardware density: Zippers, snaps, drawcords, cord stops, velcro, and buckles all require brand, size, finish, and color callouts.

- Complex construction: Taped seams, quilting patterns, bound edges, and reinforced stress points.

- Layering ease: Grading must account for wearing over base layers.

Without a complete tech pack, jackets have the highest first-sample rejection rate of any garment category — estimated at 40–50% — due to hardware mismatches, incorrect insulation weights, and construction errors that do not surface until the sample is physically tested.

Key Components of a Jacket Tech Pack

When you upload your jacket design to Adstronaut AI, the system organizes your project into the structured tabs required for complex outerwear production. Here is how each component applies to jackets.

1. Flat Sketch (Front, Back, Interior)

Unlike simpler garments that need only front and back views, jackets require a minimum of three views: front, back, and interior. The interior view is critical because it reveals lining construction, interior pocket placement, inside label positioning, and how the shell connects to the lining.

What each view must show:

- Front: Closure type, exterior pocket placement, collar/hood shape, cuff construction, hem finish.

- Back: Yoke seam, back vent (if applicable), rear panel construction, action pleats.

- Interior: Lining attachment method, interior pocket dimensions and placement, hanging loop, care label position, interior storm flap.

Adstronaut AI Feature: When you upload your jacket photo, our AI generates a clean technical flat sketch. You can use the Garment Callouts tab to annotate each view — marking zipper placement on the front, vent construction on the back, and pocket bag dimensions on the interior view.

2. Shell & Lining BOM

A jacket BOM is significantly more complex than a single-layer garment. You are managing multiple fabric layers, each with its own weight, composition, color, and supplier.

Shell Fabrics (Outer Layer):

- Nylon: Ripstop or taffeta, typically 40–70 denier. Common for lightweight outerwear.

- Polyester: Often recycled, 75–150 denier. Used in performance and puffer jackets.

- Cotton: Canvas, twill, or denim. Heavier, used for workwear and casual jackets.

- Wool: Melton, tweed, or boiled wool. Used for overcoats and blazers.

Lining Fabrics (Inner Layer):

- Taffeta: Smooth polyester, 50–70 GSM. The most common jacket lining.

- Mesh: Polyester mesh, used in ventilated athletic jackets.

- Satin: 60–80 GSM. Used in premium blazers and formal outerwear.

Interlining (Structural Layer):

- Fusible interfacing: Iron-on stiffener used in collars, cuffs, plackets, and pocket flaps to maintain shape. Specify weight (light, medium, heavy) and placement.

Each fabric entry in the BOM must include: fabric name, composition (e.g., "100% Nylon 66"), weight (GSM or denier), color (Pantone reference), width, and supplier. The Colorways tab in Adstronaut helps you organize Pantone codes across all layers.

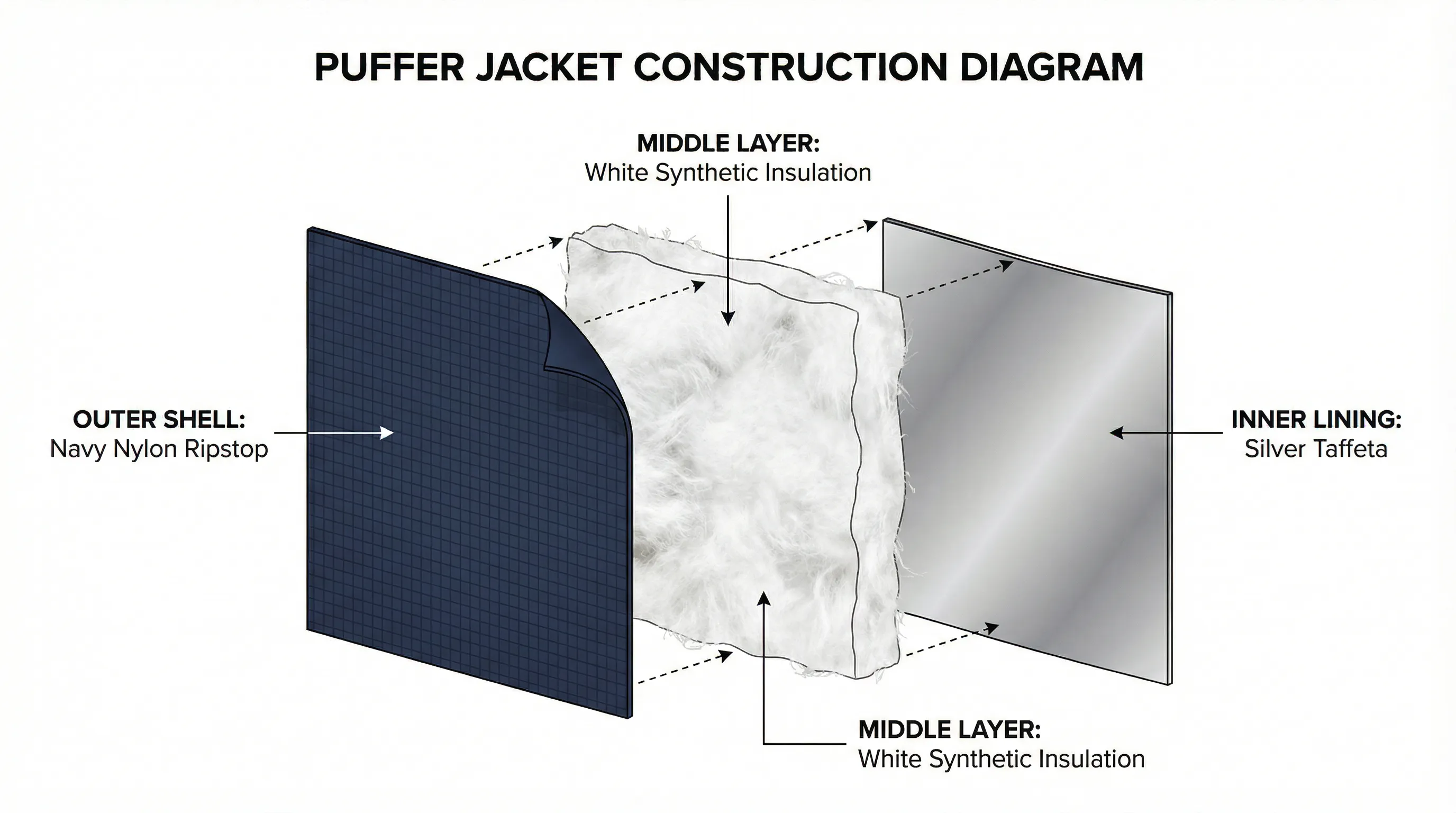

3. Insulation Specifications

If your jacket is insulated, this section is non-negotiable. Writing "padded" or "insulated" in a tech pack tells the factory nothing. You must specify the exact insulation type, weight, and performance rating.

Insulation Comparison Table:

| Type | Warmth Rating | Weight (per sq meter) | Cost Level | Wet Performance | Care |

|---|---|---|---|---|---|

| Down (550 FP) | Good | 60–100g | Medium | Poor — loses loft when wet | Dry clean or special wash |

| Down (700-800 FP) | Excellent | 40–80g | High | Poor — loses loft when wet | Dry clean or special wash |

| Down (850-900 FP) | Superior | 30–60g | Very High | Poor — loses loft when wet | Dry clean or special wash |

| Primaloft Silver | Very Good | 60–133g | Medium | Excellent — retains 98% warmth | Machine washable |

| Primaloft Gold | Excellent | 60–133g | Medium-High | Excellent — retains 98% warmth | Machine washable |

| Thinsulate | Good | 40–150g | Low-Medium | Good — retains 80% warmth | Machine washable |

| No insulation (lined) | Minimal | N/A | Low | N/A | Machine washable |

Fill power (FP) measures down quality: the higher the number, the more air one ounce of down traps, and the warmer it is per gram. The International Down and Feather Laboratory (IDFL) sets the global standard for fill power testing — your spec should reference IDFL-certified fill power ratings.

Gram weight determines warmth level for synthetic insulation: 60g is lightweight (spring/fall), 100g is midweight (cool winter), and 150g+ is heavyweight (extreme cold). Your tech pack must specify both the brand name and the gram weight — e.g., "Primaloft Silver 100g" — not just "100g synthetic."

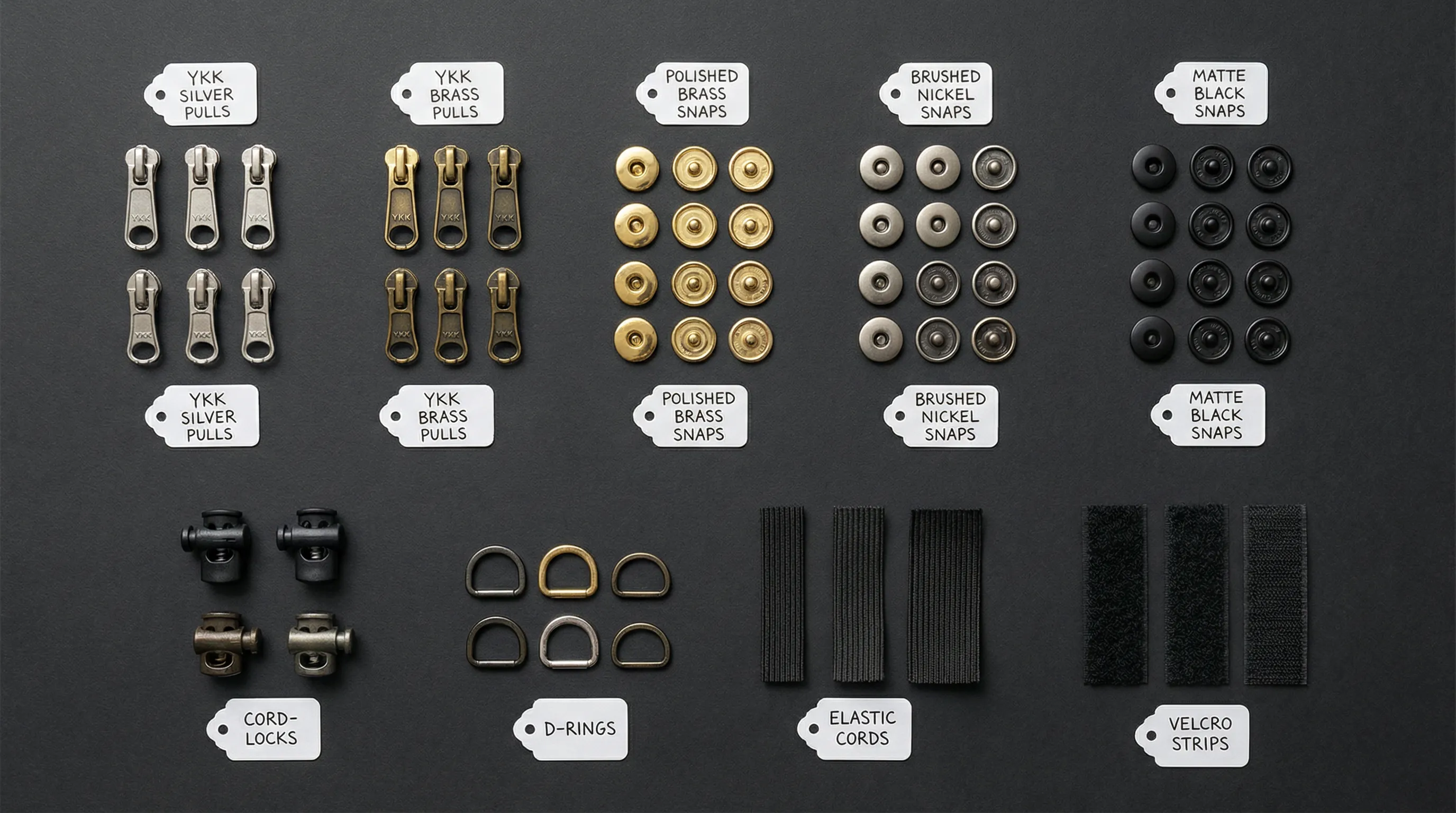

4. Closure & Hardware

Hardware is where jacket tech packs diverge most sharply from other garments. A single jacket may use three or four different closure types across the front, pockets, and hood.

Main Zipper Specifications:

- Gauge: #3 (lightweight, interior pockets), #5 (standard outerwear), #8 (heavy-duty, oversized visual)

- Brand: YKK (industry standard, premium), SBS (cost-effective alternative), Riri (luxury)

- Type: Molded plastic teeth (lightweight, colored) vs. metal teeth (durable, premium look)

- Separation: Separating (opens fully, required for front-zip jackets) vs. non-separating (pockets, interior zips)

- Pull: Specify pull design — standard, logo-debossed, cord pull, ring pull — and material (zinc alloy, plastic, rubber)

Snap Specifications:

- Ring snap: Standard outerwear snap, specify cap diameter (12mm, 15mm) and finish (matte nickel, antique brass, black oxide)

- Prong snap: Used for lighter-weight applications

- Magnetic snap: Concealed closure, specify pull strength

Additional Hardware:

- Velcro: Specify width, length, and hook-loop orientation for storm flaps and cuff adjusters

- Drawcords: Elastic vs. woven, specify diameter, cord stopper type (barrel, spring-loaded), and aglet finish

- D-rings/buckles: Specify size, material, and placement

Every hardware item must include brand, size, material, finish color (Pantone or DTM), and placement coordinates. According to industry data, roughly 30% of first-sample rejections on outerwear are caused by hardware errors — wrong zipper gauge, mismatched snap finishes, or missing cord stops.

5. Pocket Construction

Jackets often have 5–8 pockets across the exterior and interior, each with different construction methods. Every pocket needs its own specification block.

Pocket Types and Their Specs:

- Welt Pocket: An inset pocket with a narrow fabric strip (welt) finishing the opening. Specify welt width (typically 1–1.5cm), opening length, and pocket bag depth. Common on blazers and bombers.

- Flap Pocket: A welt pocket covered by a fabric flap. Specify flap dimensions, flap shape (square, rounded), and closure (none, snap, button). Common on field jackets and parkas.

- Patch Pocket: An externally applied pocket. Specify dimensions, corner shape (square, rounded), and attachment method (topstitched, edge-stitched). Common on workwear and shirt jackets.

- Zippered Pocket: A pocket concealed by a zipper. Specify zipper gauge (#3 for pockets), zipper length, and whether the zipper is exposed or concealed behind a fabric welt. Common on performance jackets.

- Interior Pocket: A pocket on the lining side. Specify placement (left chest, right chest), dimensions, closure (none, zipper, velcro, button loop), and whether it includes a media port/cord hole. Critical for securing valuables.

- Napoleon Pocket: A vertically accessed chest pocket with a side-entry zipper, positioned at an angle. Specify entry angle, zipper length, and pocket bag depth. Common on ski jackets and military-inspired designs.

For every pocket, your tech pack must include: pocket bag fabric (self-fabric, lining, or mesh), pocket bag dimensions (width x depth), placement (distance from center front, shoulder seam, or hem), and reinforcement (bar tacks at stress points, stay tape at openings).

6. Collar & Hood Details

The collar and hood area is where fit and function converge. A poorly specified collar results in drafts, discomfort, and a cheap appearance.

Collar Types:

- Stand Collar: An upright collar without a fold. Specify height (typically 5–8cm for jackets), interfacing weight, and closure (zipper coverage, snap at top).

- Convertible Collar: A collar that can be worn up or folded down. Specify both positions in the flat sketch, including snap or button placement for the "up" position.

Hood Specifications:

- Fixed Hood: Permanently attached. Specify hood height, hood depth, and face opening width. Include drawcord specs for cinching.

- Removable Hood: Specify attachment method — concealed zipper (note gauge and length) vs. snap buttons (note spacing and count). Include a detail sketch of the attachment system so the jacket looks clean with or without the hood.

- Storm Flap: A fabric strip behind the main zipper that blocks wind and rain. Specify width, closure (snaps or velcro), and position relative to the zipper. This is a frequently missed detail.

- Chin Guard: A fabric tab at the top of the zipper that prevents the pull from contacting the chin. Specify material (often fleece or soft lining fabric), dimensions, and attachment.

7. Measurements & Grading

Jacket grading differs fundamentally from base garment grading. Because jackets are worn over other clothing, the grade increments are larger to maintain consistent layering ease across sizes.

Key Measurement Points for Jackets: Chest (across at armpit), shoulder (seam to seam), sleeve length (shoulder seam to cuff), body length (HPS to hem), across back, bicep circumference, wrist/cuff opening, and hem circumference.

Jacket Grading vs. Base Garment Grading: Standard shirts grade at +1.5" per size on the chest. Jackets typically grade at +2" per size on the chest to accommodate layering. Sleeve length grades at +0.5"–0.75" per size, and body length at +0.75"–1" per size. Failing to use outerwear-specific grade rules results in larger sizes feeling tight when worn over mid-layers. For a deeper dive into grading methodology, see our size grading guide.

Sample Measurement Table — Men's Bomber Jacket (inches):

| Point of Measure | S | M | L | XL | 2XL | 3XL |

|---|---|---|---|---|---|---|

| Chest Width (1/2) | 22 | 24 | 26 | 28 | 30 | 32 |

| Shoulder Width | 17.5 | 18.5 | 19.5 | 20.5 | 21.5 | 22.5 |

| Sleeve Length | 24.5 | 25 | 25.5 | 26 | 26.5 | 27 |

| Body Length (HPS) | 25 | 26 | 27 | 28 | 29 | 30 |

| Across Back | 16 | 17 | 18 | 19 | 20 | 21 |

| Bicep (1/2) | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 |

| Cuff Opening (1/2) | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

| Hem Opening (1/2) | 17 | 18.5 | 20 | 21.5 | 23 | 24.5 |

Tolerance: +/- 0.5" on all measurements. Measurements taken with garment laid flat, closed.

Adstronaut AI Feature: The Sample Measurements tab lets you draw measurement lines directly on the generated flat sketch. The Size Table then automates the grading math once you set your grade rules, generating the full size run from your base size.

8. Construction Details

Construction specs determine durability, weatherproofing, and final price. Every seam, binding, and stitch type must be specified.

Seam Types:

- Plain seam: Standard for non-weatherproof jackets. Seam allowance typically 1cm.

- Flat-felled seam: Double-stitched, visible topstitch. Used for durability on denim jackets and workwear.

- Taped seam: A waterproof tape (typically 20–22mm wide) heat-sealed over the seam. Required for any jacket claiming waterproof performance. Specify tape width and brand.

- Sealed seam: Fully taped (all seams sealed) vs. critically taped (only shoulder, armhole, and center back sealed). Fully taped costs more but provides true waterproof protection.

Binding & Edge Finishing:

- Collar binding: Specify material (grosgrain ribbon, self-fabric, contrast tape), width, and color.

- Cuff construction: Ribbed knit (specify rib pattern, width, and spandex content) vs. adjustable tab (specify velcro or snap) vs. elastic.

- Hem finish: Elasticized (specify elastic width), drawcord (specify cord type and stopper), or clean-finished (turned and topstitched).

Quilting (if applicable):

- Specify quilting pattern: horizontal channels (specify channel width — typically 5–10cm), diamond, box, or chevron.

- Specify stitch type: single-needle lockstitch or chainstitch.

- Specify whether quilting is sewn through to the shell ("stitch-through" — creates cold spots at stitch lines) or uses internal baffles ("baffle construction" — warmer, more expensive).

Jacket Types & Their Unique Specs

Different jacket styles have distinct spec requirements. Here is a brief overview of what makes each type unique in a tech pack context.

Bomber Jacket: Ribbed knit cuffs and hem (specify rib height, tension, and spandex %), cropped body length (typically 24–27" HPS), interior pockets (usually one or two with zipper closure), minimal collar (stand or ribbed), and a single front separating zipper. The BOM is moderate — shell, lining, ribbing, one zipper, and optional interior zipper.

Parka: Extended body length (32–38" HPS), multiple closure systems (zipper + snap storm flap), fur or faux-fur trim on hood (specify attachment method — removable or fixed, and trim material), drawcord at waist for shape, fishtail or straight hem, and heavy insulation. The BOM is extensive — often 15+ line items.

Puffer Jacket: Quilting pattern and baffle construction are the defining specs. Down puffers require fill power rating, fill weight per panel, and down-proof shell fabric (specify downproof rating — must prevent feather escape). Synthetic puffers require insulation brand, gram weight, and quilting dimensions. Include a stitch-through vs. baffle callout diagram.

Denim Jacket: Similar hardware complexity to jeans — metal buttons (specify shank buttons for the front, tack buttons for pockets), rivets at stress points, contrast stitching (specify thread color and weight), and bartacks at pocket corners. Use flat-felled seams throughout. The BOM includes denim (specify weight in oz, e.g., 12oz selvedge), pocket lining, interfacing, and multiple hardware types.

Rain Jacket / Hardshell: Waterproof rating is the defining spec — measured in millimeters of hydrostatic head (e.g., 10,000mm = moderate rain, 20,000mm+ = heavy sustained rain). Must specify DWR (Durable Water Repellent) coating on the shell fabric, fully sealed seams (reference ASTM D751 for coated fabric testing), waterproof zippers, and storm flaps over all openings. Breathability rating (MVTR — moisture vapor transmission rate) should also be specified, typically in g/m2/24h.

Blazer / Structured Jacket: Canvas chest piece (fused vs. floating), pad stitching on the lapel roll line, shoulder pads (specify thickness and material), interior construction (half-lined vs. fully lined), welt pockets with flaps, sleeve buttons (specify functional vs. decorative, and button count — typically 3 or 4). This is a specialized category covered in more detail in a separate guide.

Flat lay of jacket hardware components: metal zipper pulls, snap buttons in brass and nickel, drawcord stoppers, and D-ring buckles

Flat lay of jacket hardware components: metal zipper pulls, snap buttons in brass and nickel, drawcord stoppers, and D-ring buckles

Common Jacket Tech Pack Mistakes

These are the errors that cause the most first-sample rejections in outerwear production.

1. Not specifying separate measurements for shell vs. lining. The lining must be slightly larger than the shell (typically +0.25" to +0.5" on body width and length) to allow room for movement without pulling. If you only provide one set of measurements, the factory will cut both to the same dimensions, causing the jacket to feel tight and the lining to pull when the wearer moves.

2. Missing seam-sealing specs for waterproof jackets. Specifying "waterproof fabric" but not specifying taped seams means water will penetrate at every stitch hole. You must call out which seams are taped, the tape width, and whether the jacket is fully taped or critically taped. Reference the Gore-Tex or eVent seam-sealing standards for the expected performance level.

3. Vague insulation specifications. Writing "padded" or "insulated" gives the factory no actionable information. They will use whatever fill they have in stock, which may be a 60g polyester batting that provides no warmth. Always specify the brand, type, and gram weight — e.g., "Primaloft Silver Insulation, 100g/m2" or "RDS-certified 650 fill power white goose down, 80g fill weight."

4. Forgetting to specify the zipper pull design and material. The zipper pull is the most touched and most visible hardware element on the jacket. Leaving it unspecified means the factory will attach a generic pull. If you want a custom-debossed pull, a cord pull, or a specific shape, include a detail sketch with dimensions and material callout.

5. Omitting the interior view. Skipping the interior view means the factory guesses on lining attachment, interior pocket placement, and label positioning. Always include a dedicated interior flat sketch.

Create Your Jacket Tech Pack in Minutes

Jackets are the most complex garments to spec, but that complexity makes the tech pack even more valuable. A complete jacket tech pack prevents the costly back-and-forth that eats into margins on high-value outerwear.

Adstronaut AI provides the professional structure needed to manage multiple fabric layers, hardware specs, insulation callouts, and construction details in one organized document.

- Upload your jacket photo or reference image.

- Define your shell, lining, and insulation in the BOM tabs.

- Annotate hardware, pockets, and construction details on the AI-generated sketch.

- Set your grade rules with outerwear-specific increments.

- Export a comprehensive, factory-ready PDF.

Get the most complex garment right on the first sample. Learn the full process in our how to create a tech pack guide, or see how other garment categories compare in our tech pack examples.

Generate your Jacket Tech Pack for free!

Cross-section diagram of a puffer jacket showing three layers: outer shell nylon, synthetic insulation fill, and interior taffeta lining

Cross-section diagram of a puffer jacket showing three layers: outer shell nylon, synthetic insulation fill, and interior taffeta lining

Frequently Asked Questions

How many pages should a jacket tech pack be?

A jacket tech pack typically runs 10–15 pages, depending on complexity. A simple unlined denim jacket may need 10 pages, while a fully insulated parka with removable hood, multiple pocket types, and waterproofing specs may require 15 or more. Key sections include: flat sketches (3 views), shell and lining BOM, insulation spec, hardware page, pocket detail page, measurement and grading tables, construction notes, and colorway page. Compare this to a t-shirt tech pack at 6–8 pages.

What zipper gauge should I use for outerwear?

Use #5 for standard outerwear (bombers, light jackets, parkas) and #8 for heavy-duty or oversized visual impact (workwear, oversized puffers). Use #3 for interior and pocket zippers where a smaller profile is preferred. Always specify the brand (YKK is the industry standard), tooth type (molded plastic vs. metal), and whether the zipper is separating (front-zip jackets) or non-separating (pockets). Include the pull design — cord pull, ring pull, or standard — in the hardware section.

Do I need separate specs for shell and lining?

Yes, absolutely. The shell and lining are different fabrics with different weights, compositions, and often different colors. They must appear as separate line items in the BOM with individual specs for each. The lining measurements should be slightly larger than the shell (typically +0.25" to +0.5") to allow comfortable movement. If your jacket has an interlining or insulation layer, that is a third distinct entry. Failing to separate these is one of the top causes of jacket sample rejection.

How do I spec waterproofing in a tech pack?

Waterproofing requires four specifications: (1) Shell fabric waterproof rating in mm of hydrostatic head (10,000mm for moderate rain, 20,000mm+ for heavy rain); (2) DWR (Durable Water Repellent) coating on the shell — specify type (C0 fluorine-free or C6) and durability rating; (3) Seam sealing — specify fully taped or critically taped, tape width (20–22mm standard), and application method; (4) Waterproof zippers on all openings (specify brand and type — e.g., YKK Aquaguard). Reference ASTM D751 for coated fabric testing standards.

What insulation should I choose for my jacket?

It depends on your target warmth, price point, and care requirements. Down (650–800 fill power) offers the best warmth-to-weight ratio but loses performance when wet and requires special washing. Primaloft (100g) delivers comparable warmth to 650 FP down, retains 98% of insulation when wet, and is machine washable — making it the best all-around choice for most brands. Thinsulate is the most affordable option and performs well in moderate cold. Always specify the exact brand and gram weight (e.g., "Primaloft Silver 100g"), never just "synthetic padding." The IDFL (International Down and Feather Laboratory) certifies fill power ratings if you are using down.

How does jacket grading differ from other garments?

Jacket grading uses larger increments than base garments to account for layering. Where a shirt might grade +1.5" per size on the chest, a jacket typically grades +2" per size on the chest. Sleeve length grades at +0.5"–0.75" per size (same as shirts), but body length may grade at +0.75"–1" per size. The bicep and cuff also need slightly more ease than fitted garments. If you use standard shirt grading on a jacket, larger sizes will feel restrictive when worn over a hoodie or sweater.

Do I need to include an interior view in my tech pack?

Yes. An interior view is essential for any lined jacket. It shows the factory where to place interior pockets, how to attach the lining to the shell (tacked at seams, fully sewn, or free-floating), where the care label and brand label sit, and how the facing/placket is constructed. Without this view, factories frequently misplace interior pockets, attach linings incorrectly, or position labels in uncomfortable locations. Provide a clean flat sketch of the jacket opened flat, interior side facing up.

What is a DWR coating?

DWR stands for Durable Water Repellent. It is a chemical treatment applied to the outer surface of a jacket's shell fabric that causes water to bead up and roll off rather than soaking into the fabric. DWR is not waterproofing — it is a surface treatment that works in conjunction with a waterproof membrane or coating. Specify the DWR type in your tech pack: C0 (fluorine-free, environmentally preferred) or C6 (fluorocarbon-based, higher performance but being phased out). Note that DWR performance degrades over time with washing and abrasion, and can be restored with spray-on or wash-in DWR treatments. Include this in the care label instructions.

Sources and further reading:

- ASTM D751 — Standard Test Methods for Coated Fabrics (waterproof membrane and coated fabric testing standards for outerwear)

- IDFL (International Down and Feather Laboratory) — Fill Power Testing Standards (global standards for down insulation quality certification)

- Gore-Tex / eVent — Waterproofing and seam-sealing performance benchmarks (referenced for hydrostatic head and breathability ratings)

- Maker's Row — Outerwear Manufacturing Guide (factory requirements and hardware sourcing for jacket production)

- Allied Market Research — Global Outerwear Market Report (market size and growth projections for the outerwear segment)

- Adstronaut AI — The Complete Guide to Fashion Tech Packs (comprehensive tech pack overview)